Advancements in Industrial IoT

The Industrial Control for Process Automation Market is significantly influenced by advancements in the Industrial Internet of Things (IIoT). The integration of IIoT technologies enables real-time monitoring and control of industrial processes, leading to improved efficiency and reduced operational costs. As sensors and connected devices become more prevalent, industries are leveraging data analytics to enhance predictive maintenance and minimize downtime. The IIoT market is expected to witness substantial growth, with estimates suggesting it could reach a valuation of over 1 trillion dollars by 2025. This technological evolution is likely to reshape the landscape of process automation, making it more responsive and adaptable to changing operational demands.

Growing Focus on Energy Efficiency

The Industrial Control for Process Automation Market is witnessing a growing focus on energy efficiency as organizations strive to reduce operational costs and environmental impact. Automation technologies play a crucial role in optimizing energy consumption by enabling precise control over industrial processes. This shift towards energy-efficient solutions is driven by both regulatory pressures and corporate sustainability goals. Data indicates that energy-efficient automation systems can reduce energy consumption by up to 30%, making them an attractive investment for industries looking to enhance their sustainability profile. As energy costs continue to rise, the demand for innovative automation solutions that promote energy efficiency is likely to increase, further propelling market growth.

Integration of Artificial Intelligence

The Industrial Control for Process Automation Market is increasingly integrating artificial intelligence (AI) into automation systems. AI technologies enhance the capabilities of traditional automation by enabling predictive analytics, machine learning, and advanced data processing. This integration allows for more intelligent decision-making and process optimization, which can lead to significant cost savings and improved operational performance. Industries are beginning to recognize the potential of AI to transform their automation strategies, with forecasts suggesting that AI in industrial applications could reach a market size of over 15 billion dollars by 2025. The adoption of AI-driven automation solutions is likely to redefine operational paradigms, making processes more agile and responsive to market demands.

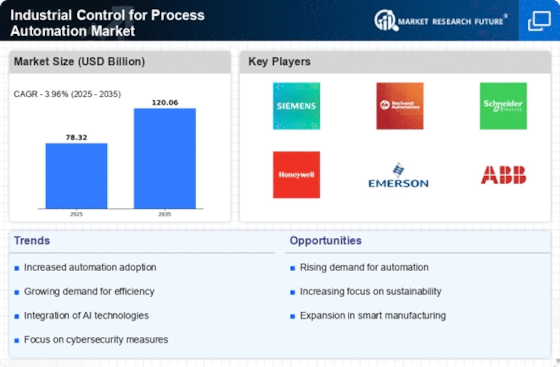

Increased Demand for Automation Solutions

The Industrial Control for Process Automation Market is experiencing a notable surge in demand for automation solutions. This trend is primarily driven by the need for enhanced operational efficiency and productivity across various sectors. Industries such as manufacturing, oil and gas, and pharmaceuticals are increasingly adopting automation technologies to streamline processes and reduce human error. According to recent data, the automation market is projected to grow at a compound annual growth rate of approximately 9% over the next five years. This growth is indicative of a broader shift towards automated systems that can provide real-time data and analytics, thereby facilitating informed decision-making and optimizing resource allocation.

Regulatory Compliance and Safety Standards

The Industrial Control for Process Automation Market is increasingly shaped by stringent regulatory compliance and safety standards. Industries are compelled to adopt advanced automation solutions to meet these regulations, which aim to enhance safety and environmental sustainability. Compliance with standards such as ISO 9001 and OSHA regulations necessitates the implementation of automated systems that can ensure consistent quality and safety in operations. As a result, companies are investing in process automation technologies that not only comply with regulations but also improve overall operational integrity. This trend is expected to drive market growth, as organizations prioritize compliance to mitigate risks and enhance their reputational standing.