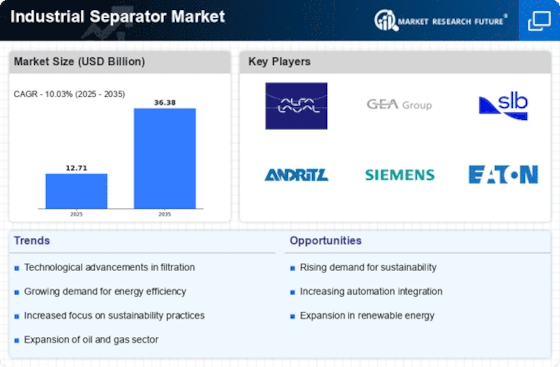

Leading market players are investing heavily in research and development in order to expand their product lines, which will help the Industrial Separator Market, grow even more. Market participants are also undertaking a variety of strategic activities to expand their footprint, with important market developments including new product launches, contractual agreements, mergers and acquisitions, higher investments, and collaboration with other organizations. To expand and survive in a more competitive and rising market climate, Industrial Separatorindustry must offer cost-effective items.

Manufacturing locally to minimize operational costs is one of the key business tactics used by manufacturers in the Industrial Separator industry to benefit clients and increase the market sector. In recent years, the Industrial Separator industry has offered some of the most significant advantages to medicine. Major players in the Industrial Separator Market, including eSolar Inc. (US), SolarReserve (US), ACWA Power (Saudi Arabia), Chiyoda Corporation (Japan), Alsolen (Morocco), and Soligua (Italy) and others, are attempting to increase market demand by investing in research and development operations.

Goudsmit Magnetics is a worldwide industrial firm that designs and manufactures magnets and magnetic systems for metal separation, recycling, transportation, lifting, holding, and demagnetisation in a variety of industries. Years of collected knowledge and cutting-edge engineering, combined with intensive communication between the company, original equipment manufacturer, and end user, result in functional tailored solutions. Since its inception in 1959, this family-owned business has manufactured millions of magnetic systems that have found their way to every continent. The headquarters in the Netherlands are where development and engineering take place.

The organization's cornerstones are innovation and quality in accordance with ISO 9001:2008, ISO/TS 16949:2009, and AS9100c standards, as well as EHEDG & VDA 6.3.

In September Goudsmit Magnetics has released a new version of its easily cleanable Easy Clean Flow magnet. In the food, chemicals, ceramics, and plastics sectors, this magnetic separator is predicted to extract metal particles and weakly magnetic stainless steel particles from powders as small as 30 pm.

ERIE GROUP INTERNATIONAL, INC. is a business located at 401 7TH AVE in Erie, Illinois. ERIE is a family-owned business that has been in business since 1938 and specialises in dairy protein components. ERIE is a market leader in the production and distribution of milk protein constituents such as acid casein, calcium, sodium, and potassium caseinates, MPC, and MPI. Customizable milk protein crisps and granulated calcium carbonate are among ERIE's speciality products.

In November Erie announced the development of its manufacturing plant in the United States to support strategic growth plans for repair, testing, and R&D activities.

This expansion is designed to boost the company's repair business, ease product development, and improve testing support for its goods.