Rising Demand in Consumer Goods

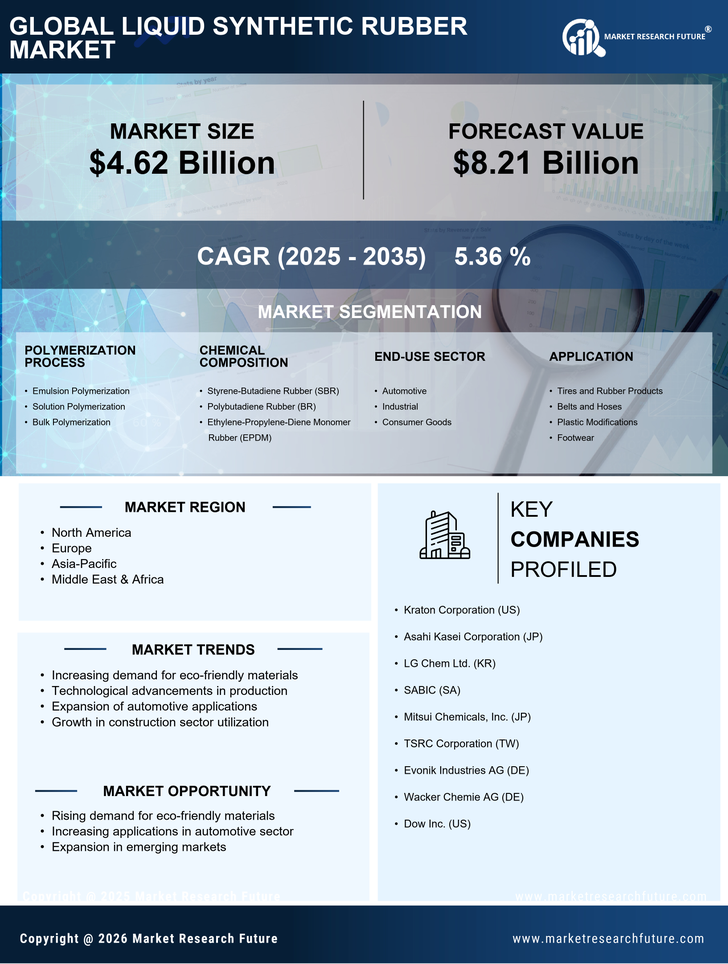

The Liquid Synthetic Rubber Market is experiencing a surge in demand from the consumer goods sector, particularly in the production of footwear, sports equipment, and household items. Liquid synthetic rubber is favored for its flexibility, durability, and resistance to wear and tear, making it an ideal material for various consumer products. As disposable income levels rise and consumer preferences shift towards high-quality goods, the market for liquid synthetic rubber is expected to expand. In 2025, the consumer goods sector is anticipated to contribute significantly to the overall market growth, with an estimated increase of 6% in demand for synthetic rubber products. This trend indicates a robust potential for manufacturers to capitalize on the evolving consumer landscape.

Growth in Construction Activities

The construction industry significantly influences the Liquid Synthetic Rubber Market, driven by the increasing need for durable and flexible materials in various applications. Liquid synthetic rubber is utilized in sealants, adhesives, and coatings, which are essential for modern construction projects. As urbanization accelerates, the demand for infrastructure development rises, leading to a projected growth rate of around 5% in the construction sector by 2026. This growth is likely to enhance the consumption of liquid synthetic rubber, as builders and contractors seek materials that offer superior performance and longevity. Additionally, the trend towards sustainable construction practices may further increase the adoption of liquid synthetic rubber, as it can be formulated to meet environmental standards.

Technological Innovations in Production

Technological advancements in the production processes of liquid synthetic rubber are poised to drive the Liquid Synthetic Rubber Market forward. Innovations such as improved polymerization techniques and the development of more efficient catalysts are enhancing the quality and performance of synthetic rubber. These advancements not only reduce production costs but also enable manufacturers to create specialized products tailored to specific applications. As of 2025, the market is witnessing a shift towards more sustainable production methods, which could potentially reduce the environmental impact associated with synthetic rubber manufacturing. This focus on innovation is likely to attract investments and foster competition among key players, further propelling market growth.

Increasing Demand from Automotive Sector

The automotive sector is a primary driver for the Liquid Synthetic Rubber Market, as it increasingly adopts synthetic rubber for tire manufacturing and other components. The demand for high-performance tires, which utilize liquid synthetic rubber for enhanced durability and performance, is on the rise. In 2025, the automotive industry is projected to account for approximately 40% of the total consumption of synthetic rubber. This trend is likely to continue as manufacturers seek to improve fuel efficiency and reduce emissions, thereby increasing the need for advanced materials. Furthermore, the shift towards electric vehicles is expected to further bolster the demand for liquid synthetic rubber, as these vehicles require specialized tires that can withstand different performance parameters.

Environmental Regulations and Sustainability Trends

The Liquid Synthetic Rubber Market is increasingly influenced by stringent environmental regulations and a growing emphasis on sustainability. Governments and regulatory bodies are implementing policies aimed at reducing the environmental impact of synthetic materials, which is prompting manufacturers to adopt greener practices. The development of bio-based synthetic rubber alternatives is gaining traction, as companies seek to align with sustainability goals. By 2025, it is expected that a significant portion of the market will shift towards eco-friendly products, driven by consumer demand for sustainable options. This transition not only presents challenges but also opportunities for innovation within the liquid synthetic rubber sector, as companies strive to meet regulatory requirements while maintaining product performance.