Aerospace Industry Demand

The aerospace industry demand is a crucial driver for the Long Fiber Thermoset Composite Market. As aerospace manufacturers strive for improved performance and reduced weight in aircraft design, the adoption of advanced composite materials is accelerating. Long fiber thermoset composites are particularly valued for their strength and thermal stability, making them ideal for critical components. The market is projected to experience substantial growth, with estimates suggesting an increase in aerospace applications by approximately 30% over the next five years. This trend highlights the aerospace sector's commitment to innovation and efficiency, further propelling the demand for high-performance composite materials.

Growing Automotive Sector

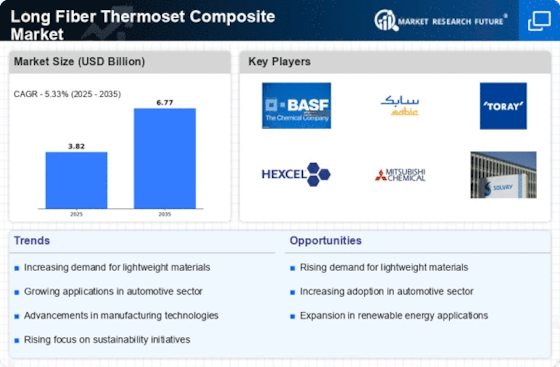

The growing automotive sector significantly impacts the Long Fiber Thermoset Composite Market. As manufacturers seek to enhance fuel efficiency and reduce emissions, lightweight materials are becoming essential. Long fiber thermoset composites offer an attractive solution due to their high strength-to-weight ratio. The automotive industry is increasingly incorporating these materials into vehicle components, which is expected to drive market growth. Recent data indicates that the use of composites in automotive applications could increase by over 25% in the next decade. This trend reflects a broader shift towards sustainable and efficient manufacturing practices within the automotive sector.

Sustainability Initiatives

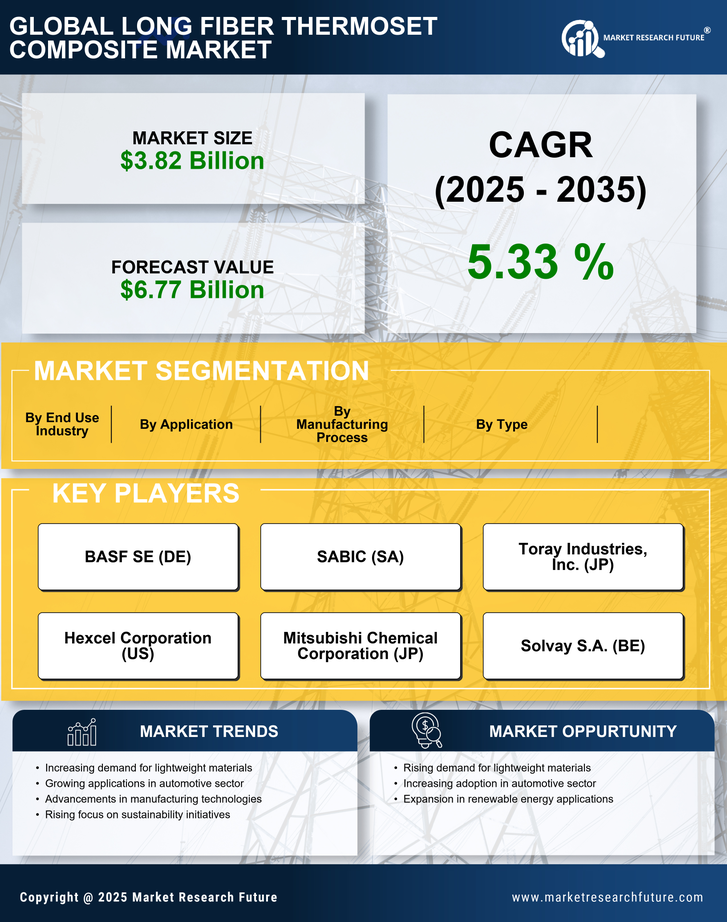

The Long Fiber Thermoset Composite Market is increasingly influenced by sustainability initiatives. As industries strive to reduce their carbon footprint, the demand for eco-friendly materials rises. Long fiber thermoset composites, known for their durability and recyclability, align well with these initiatives. Companies are investing in research to develop bio-based thermoset composites, which could further enhance their appeal. The market for sustainable composites is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 10% in the coming years. This shift towards sustainability not only meets regulatory requirements but also caters to consumer preferences for environmentally responsible products.

Technological Advancements

Technological advancements play a pivotal role in shaping the Long Fiber Thermoset Composite Market. Innovations in manufacturing processes, such as automated fiber placement and advanced molding techniques, enhance the efficiency and quality of composite production. These advancements enable the creation of lighter, stronger materials that meet the rigorous demands of various applications, including automotive and aerospace. The market is witnessing a surge in the adoption of smart composites, which integrate sensors and other technologies. This trend is expected to drive growth, with projections indicating a potential increase in market size by approximately 15% over the next five years, as industries seek to leverage these cutting-edge materials.

Customization and Versatility

Customization and versatility are critical drivers in the Long Fiber Thermoset Composite Market. Manufacturers are increasingly offering tailored solutions to meet specific customer requirements across diverse sectors. The ability to modify properties such as strength, weight, and thermal resistance allows for a broader range of applications, from construction to consumer goods. This adaptability is particularly appealing in industries that demand high-performance materials. Market data suggests that the demand for customized composites is on the rise, with a projected increase in market share of around 20% in the next few years. This trend underscores the importance of flexibility in product offerings to capture a wider customer base.