Growth of the Aging Population

The growth of the aging population is a significant driver of the Medical Injection Molding Market. As the global demographic shifts towards an older population, there is an increasing prevalence of chronic diseases that require medical intervention. This demographic trend is expected to result in a higher demand for medical devices, particularly those used in home healthcare settings. The World Health Organization estimates that by 2050, the number of people aged 60 years and older will reach 2 billion, which will likely lead to an increased need for medical products. Consequently, manufacturers are focusing on scalable injection molding solutions to meet this rising demand, thereby enhancing the Medical Injection Molding Market.

Innovations in Material Science

Innovations in material science are significantly influencing the Medical Injection Molding Market. The development of advanced polymers and biocompatible materials has expanded the possibilities for medical device manufacturing. These materials offer enhanced performance characteristics, such as improved durability and reduced risk of contamination. For example, the introduction of thermoplastic elastomers (TPEs) has enabled the production of flexible and soft-touch medical components. As the demand for high-performance medical devices continues to rise, manufacturers are increasingly turning to these innovative materials, thereby driving growth in the Medical Injection Molding Market. This trend suggests a shift towards more sophisticated and specialized medical products.

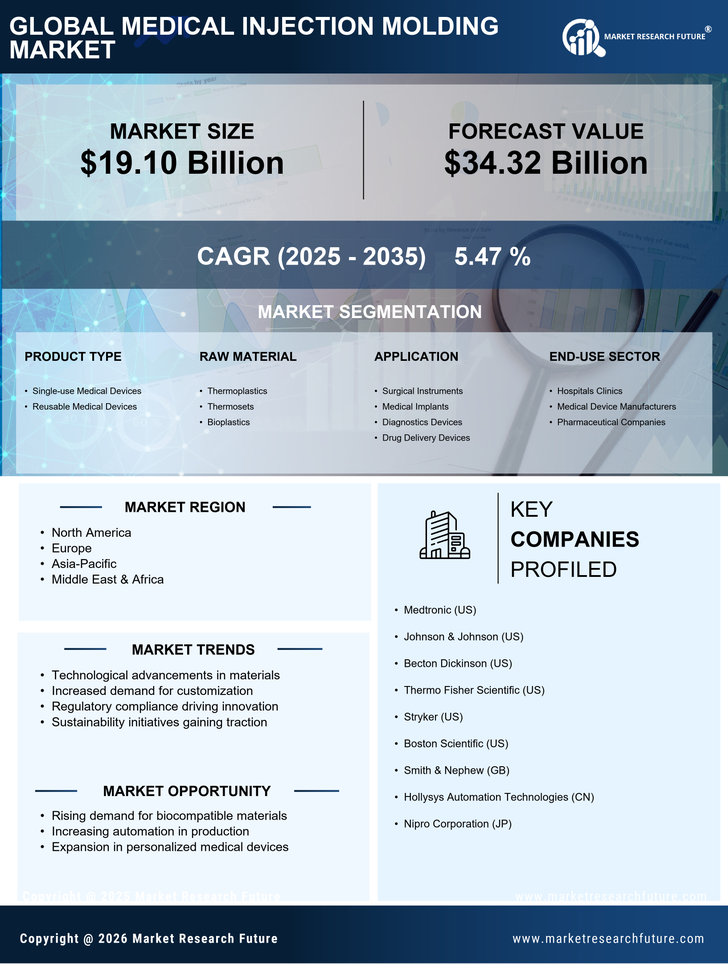

Rising Demand for Medical Devices

The increasing demand for medical devices is a primary driver of the Medical Injection Molding Market. As healthcare systems evolve, there is a notable rise in the production of devices such as syringes, catheters, and surgical instruments. According to recent data, the medical device market is projected to reach approximately 600 billion USD by 2025, which directly correlates with the need for efficient manufacturing processes like injection molding. This method allows for high precision and scalability, making it ideal for producing complex medical components. Consequently, manufacturers are investing in advanced injection molding technologies to meet the growing demand, thereby propelling the Medical Injection Molding Market forward.

Emergence of Minimally Invasive Procedures

The emergence of minimally invasive procedures is reshaping the Medical Injection Molding Market. These procedures, which require specialized medical devices, are gaining popularity due to their benefits, including reduced recovery times and lower risk of complications. As healthcare providers increasingly adopt these techniques, the demand for precision-engineered components produced through injection molding is expected to rise. The market for minimally invasive surgical devices is projected to grow significantly, indicating a robust opportunity for injection molding manufacturers. This trend underscores the importance of innovation and adaptability in the Medical Injection Molding Market, as companies strive to meet the evolving needs of healthcare professionals and patients.

Regulatory Compliance and Quality Standards

Regulatory compliance plays a crucial role in the Medical Injection Molding Market. Stringent regulations imposed by health authorities ensure that medical products meet safety and efficacy standards. For instance, the FDA and ISO standards require manufacturers to adhere to rigorous quality control processes. This has led to an increased focus on precision engineering and quality assurance in injection molding processes. As a result, companies are adopting advanced technologies and materials to ensure compliance, which in turn drives growth in the Medical Injection Molding Market. The emphasis on quality not only enhances product reliability but also fosters consumer trust, further stimulating market expansion.