Advancements in Material Science

Innovations in material science are significantly influencing the Micro Injection Molding Medical Devices Market. The development of biocompatible and biodegradable materials has opened new avenues for device manufacturing, allowing for the creation of safer and more effective medical products. For instance, the introduction of advanced polymers that can withstand sterilization processes while maintaining structural integrity is becoming increasingly common. This evolution in materials not only enhances the performance of medical devices but also aligns with regulatory standards, which are becoming more stringent. As a result, manufacturers are likely to invest in research and development to leverage these materials, thereby driving growth in the micro injection molding sector.

Regulatory Compliance and Quality Standards

The stringent regulatory environment surrounding medical devices is a critical driver for the Micro Injection Molding Medical Devices Market. Compliance with international quality standards is essential for manufacturers aiming to enter or expand in this market. Regulatory bodies are increasingly emphasizing the need for high-quality, reliable products, which necessitates the adoption of advanced manufacturing techniques such as micro injection molding. This method not only ensures precision but also facilitates the production of complex geometries that meet regulatory requirements. As a result, companies are likely to invest in quality assurance processes and technologies to adhere to these standards, thereby fostering growth in the micro injection molding sector.

Increased Focus on Patient-Centric Solutions

The Micro Injection Molding Medical Devices Market is experiencing a notable shift towards patient-centric solutions. This trend is characterized by the development of devices that prioritize user experience and comfort, which is becoming increasingly important in healthcare. Manufacturers are now focusing on creating products that are not only functional but also tailored to meet the specific needs of patients. This includes ergonomic designs and customizable features that enhance usability. As healthcare providers aim to improve patient satisfaction and outcomes, the demand for such innovative solutions is expected to rise. Consequently, this focus on patient-centricity is likely to propel the growth of the micro injection molding market, as companies strive to differentiate their offerings in a competitive landscape.

Growing Aging Population and Chronic Diseases

The demographic shift towards an aging population, coupled with the rising prevalence of chronic diseases, is a significant driver for the Micro Injection Molding Medical Devices Market. As the global population ages, the demand for medical devices that cater to age-related health issues is expected to increase. Chronic conditions such as diabetes and cardiovascular diseases require advanced medical solutions, many of which rely on micro injection molded components for their efficacy. The market is projected to witness substantial growth as healthcare systems adapt to these demographic changes, necessitating the development of innovative medical devices that can address the unique needs of older patients. This trend underscores the importance of micro injection molding technology in creating effective healthcare solutions.

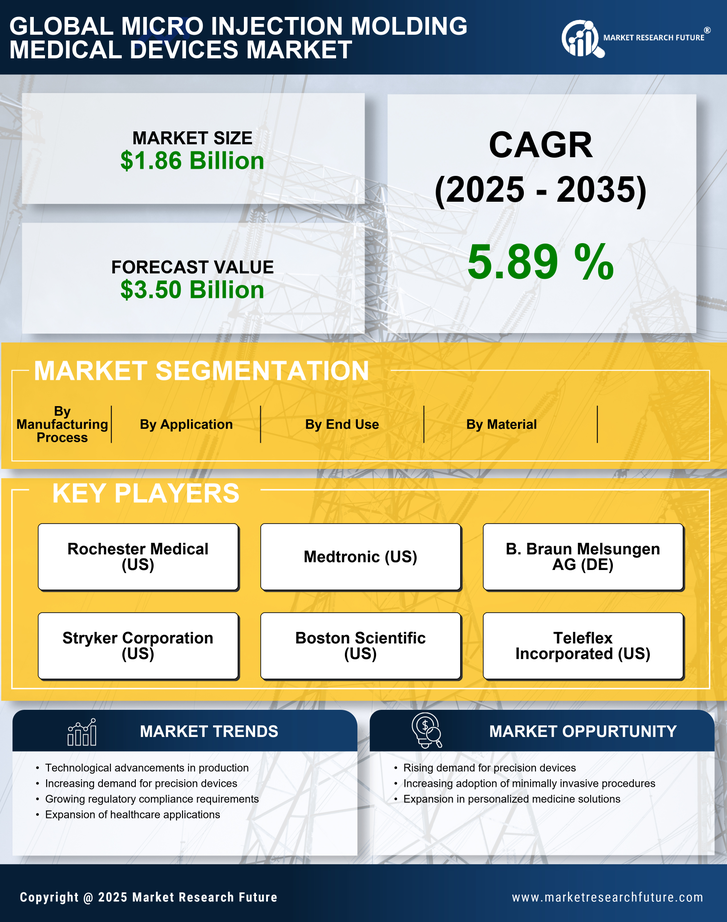

Rising Demand for Minimally Invasive Procedures

The increasing preference for minimally invasive procedures is a pivotal driver for the Micro Injection Molding Medical Devices Market. As healthcare providers and patients alike seek alternatives to traditional surgical methods, the demand for devices that facilitate such procedures has surged. This trend is evidenced by a projected growth rate of approximately 8% annually in the sector, reflecting a shift towards less invasive options. Micro injection molding technology plays a crucial role in producing intricate components that are essential for these devices, ensuring precision and reliability. Consequently, the market for micro injection molded medical devices is likely to expand as more healthcare facilities adopt these advanced techniques, thereby enhancing patient outcomes and reducing recovery times.