Regulatory Compliance

Regulatory compliance is becoming increasingly stringent, influencing the dynamics of the Metallic Powder Coating Market. Governments worldwide are implementing regulations aimed at reducing harmful emissions and promoting safer coating practices. As a result, manufacturers are compelled to adopt powder coatings that comply with these regulations, which often favor low-VOC and environmentally friendly options. This regulatory landscape not only drives the demand for compliant products but also encourages innovation in the development of new formulations that meet these standards. The market is expected to see a shift towards coatings that not only fulfill aesthetic requirements but also adhere to evolving regulatory frameworks, thereby enhancing their marketability.

Growing Automotive Sector

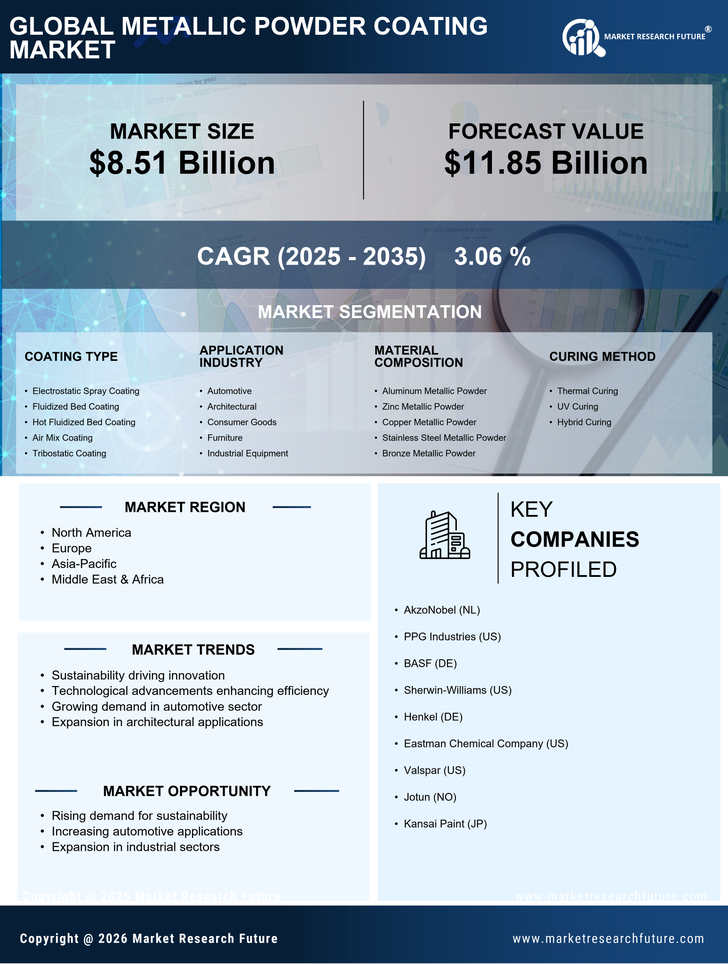

The burgeoning automotive sector is a significant driver for the Metallic Powder Coating Market. As automotive manufacturers seek to enhance vehicle aesthetics and performance, the demand for high-quality powder coatings is on the rise. These coatings offer superior durability, resistance to scratches, and a wide range of color options, making them ideal for automotive applications. The market for automotive powder coatings is projected to grow substantially, with estimates suggesting a CAGR of around 7% over the next few years. This growth is fueled by the increasing production of vehicles and the rising consumer preference for customized finishes, positioning the metallic powder coating sector as a critical component in the automotive supply chain.

Technological Innovations

Technological advancements play a pivotal role in shaping the Metallic Powder Coating Market. Innovations in application techniques, such as electrostatic spray and fluidized bed processes, enhance the efficiency and quality of powder coatings. These technologies enable uniform coating thickness and improved adhesion, which are critical for various applications, including automotive and industrial sectors. Furthermore, the development of advanced formulations, such as hybrid powder coatings, is expanding the performance capabilities of these coatings. The market is expected to benefit from ongoing research and development efforts, which could lead to the introduction of new products with enhanced properties, thereby driving growth in the industry.

Sustainability Initiatives

The increasing emphasis on sustainability within the Metallic Powder Coating Market is driving demand for eco-friendly coating solutions. Manufacturers are increasingly adopting powder coatings due to their lower volatile organic compound (VOC) emissions compared to traditional liquid coatings. This shift aligns with global environmental regulations aimed at reducing pollution and promoting sustainable practices. As a result, the market is witnessing a surge in the development of bio-based and recyclable powder coatings, which not only meet regulatory standards but also appeal to environmentally conscious consumers. The market for powder coatings is projected to grow at a compound annual growth rate (CAGR) of approximately 6% over the next few years, indicating a robust trend towards sustainable solutions in the industry.

Diverse End-User Industries

The versatility of metallic powder coatings is a key driver in the Metallic Powder Coating Market, as they find applications across a wide range of sectors. Industries such as automotive, aerospace, furniture, and electronics are increasingly adopting powder coatings due to their durability, aesthetic appeal, and resistance to corrosion. For instance, the automotive sector is projected to account for a significant share of the market, driven by the demand for high-performance coatings that can withstand harsh environmental conditions. Additionally, the furniture industry is embracing powder coatings for their ability to provide a smooth finish and vibrant colors. This broad applicability across various end-user industries is likely to sustain growth in the market.