Growth in Consumer Electronics

The Nitrile Butadiene Rubber Nbr Foam Product Market is witnessing notable growth driven by the rising demand in the consumer electronics sector. NBR foam is increasingly used in the production of cushioning materials for electronic devices, providing protection against shocks and vibrations. The proliferation of smartphones, tablets, and wearable technology has led to a heightened need for durable and lightweight materials, positioning NBR foam as a preferred choice. Market data suggests that the consumer electronics segment is projected to contribute significantly to the overall market growth, as manufacturers seek to enhance product durability and user experience through innovative materials.

Expansion of Automotive Applications

The Nitrile Butadiene Rubber Nbr Foam Product Market is significantly benefiting from the expansion of automotive applications. NBR foam is increasingly utilized in vehicle interiors, providing sound insulation, vibration dampening, and thermal protection. As the automotive industry evolves towards more efficient and comfortable vehicles, the demand for high-performance materials like NBR foam is likely to rise. Recent statistics indicate that the automotive sector represents a considerable portion of the NBR foam market, driven by the need for lightweight and durable components. This trend is expected to continue as manufacturers seek to enhance vehicle performance and passenger comfort.

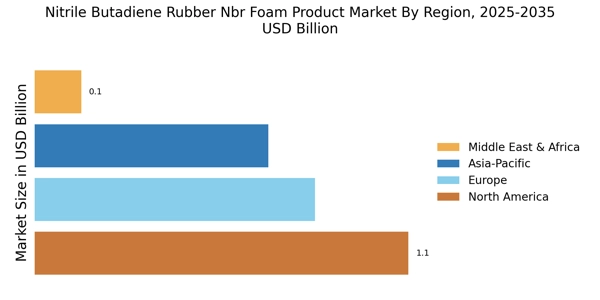

Emerging Markets and Economic Development

The Nitrile Butadiene Rubber Nbr Foam Product Market is poised for growth due to the emergence of new markets and economic development in various regions. As developing economies industrialize, the demand for NBR foam products is likely to increase across multiple sectors, including construction, automotive, and consumer goods. The expansion of manufacturing capabilities and infrastructure projects in these regions presents a significant opportunity for NBR foam manufacturers. Market analysis indicates that the growth in emerging markets could lead to a substantial increase in the consumption of NBR foam products, thereby driving overall market growth and diversification.

Increasing Applications in Industrial Sectors

The Nitrile Butadiene Rubber Nbr Foam Product Market is experiencing a surge in demand due to its increasing applications across various industrial sectors. Industries such as manufacturing, construction, and aerospace are increasingly utilizing NBR foam products for their excellent resistance to oils, chemicals, and temperature variations. This versatility allows NBR foam to be employed in gaskets, seals, and insulation materials, thereby enhancing operational efficiency. According to recent data, the industrial sector accounts for a substantial share of the NBR foam market, indicating a robust growth trajectory. As industries continue to expand and innovate, the reliance on NBR foam products is likely to increase, further driving market growth.

Rising Awareness of Health and Safety Standards

The Nitrile Butadiene Rubber Nbr Foam Product Market is positively influenced by the growing awareness of health and safety standards across various sectors. As industries prioritize worker safety and compliance with regulations, the demand for high-quality NBR foam products is likely to increase. NBR foam is known for its non-toxic properties and resistance to harmful chemicals, making it suitable for applications in healthcare, food processing, and pharmaceuticals. The emphasis on maintaining safe working environments is expected to drive the adoption of NBR foam products, thereby contributing to market expansion. This trend aligns with the broader movement towards sustainable and safe materials in industrial applications.