Technological Innovations

Technological advancements play a pivotal role in shaping the Plate Frame Heat Exchangers Market. Innovations in materials, design, and manufacturing processes are enhancing the performance and reliability of plate frame heat exchangers. For instance, the introduction of advanced gasket materials and improved plate designs has led to increased thermal efficiency and reduced maintenance requirements. Furthermore, the integration of smart technologies, such as IoT-enabled monitoring systems, is enabling real-time performance tracking and predictive maintenance. This evolution in technology is expected to drive market growth, as industries seek to leverage these advancements to improve operational efficiency and reduce downtime. The market is projected to expand as manufacturers continue to invest in research and development to meet the evolving needs of end-users.

Growth in Industrial Applications

The Plate Frame Heat Exchangers Market is witnessing substantial growth due to the expanding range of industrial applications. Industries such as oil and gas, pharmaceuticals, and power generation are increasingly utilizing plate frame heat exchangers for their superior heat transfer capabilities and compact design. The versatility of these exchangers allows for their integration into various processes, enhancing operational efficiency. Market data indicates that the industrial sector accounts for over 60% of the total demand for heat exchangers, with plate frame designs gaining traction due to their ability to handle high pressures and temperatures. This trend suggests a robust future for the plate frame heat exchangers market as industries continue to innovate and optimize their processes.

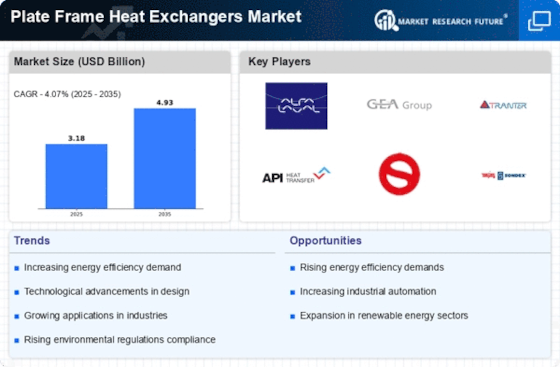

Rising Demand for Energy Efficiency

The Plate Frame Heat Exchangers Market is experiencing a notable surge in demand driven by the increasing emphasis on energy efficiency across various sectors. Industries are actively seeking solutions that minimize energy consumption while maximizing heat transfer efficiency. This trend is particularly evident in sectors such as food and beverage, chemical processing, and HVAC, where energy costs constitute a significant portion of operational expenses. According to recent data, the energy efficiency market is projected to grow at a compound annual growth rate of approximately 8% over the next five years. As organizations strive to meet sustainability goals, the adoption of plate frame heat exchangers is likely to rise, positioning them as a critical component in energy management strategies.

Expansion of Renewable Energy Sector

The Plate Frame Heat Exchangers Market is poised for growth due to the expansion of the renewable energy sector. As countries invest in alternative energy sources such as solar, wind, and bioenergy, the demand for efficient heat exchange solutions is on the rise. Plate frame heat exchangers are particularly well-suited for applications in biomass energy production and geothermal systems, where efficient heat transfer is crucial for maximizing energy output. Market analysis indicates that the renewable energy sector is expected to grow at a rate of 12% over the next decade, creating new opportunities for plate frame heat exchanger manufacturers. This trend underscores the potential for innovation and adaptation within the industry as it aligns with the global shift towards sustainable energy solutions.

Increasing Focus on Environmental Regulations

The Plate Frame Heat Exchangers Market is significantly influenced by the tightening of environmental regulations aimed at reducing emissions and promoting sustainable practices. Governments and regulatory bodies are implementing stringent guidelines that require industries to adopt cleaner technologies and improve energy efficiency. As a result, there is a growing need for heat exchangers that not only comply with these regulations but also contribute to overall sustainability goals. The market is likely to benefit from this trend, as companies seek to upgrade their existing systems to meet compliance standards. Data suggests that the market for environmentally friendly heat exchangers is expected to grow by approximately 10% annually, reflecting the increasing importance of regulatory compliance in driving demand for plate frame heat exchangers.