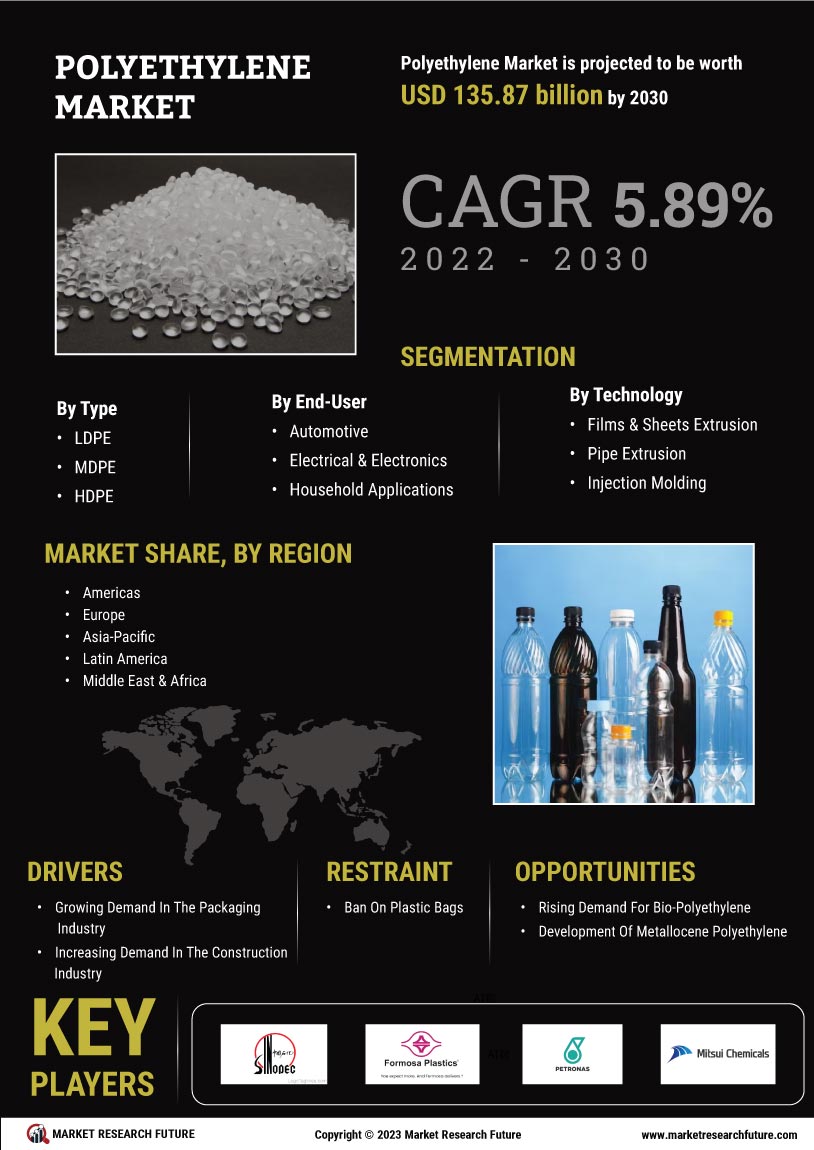

Leading market players are investing heavily in research and development activities in order to grow their product lines and service offerings, which will help the Polyethylene Market, grow even more. Market participants are also adopting a variety of strategies to extend their presence, with important market developments including new product launches, partnerships, contractual agreements, mergers and acquisitions, higher investments, and collaboration with other organizations. To grow and survive in a more competitive and rising market climate, Polyethylene industry must offer cost-effective items.

Manufacturing locally to minimize operational expenses is one of the key business practices used by manufacturers in the Polyethylene industry to benefit clients and increase the market sector. In recent years, the Polyethylene industry has offered some of the most significant advantages to medicine. Major players in the Polyethylene Market, including China Petrochemical Corporation, Formosa Plastics Corporation, Petronas Chemicals Group, Mitsui Chemicals Inc., Exxon Mobil Corporation, LyondellBasell Industries NV, Sumitomo Chemical, SABIC, Ineos Group Holdings, Sasol Ltd., Chevron Philips chemical company, and others, are attempting to increase market demand by investing in research and development operations.

Petrochemical and petroleum products are produced by China Petrochemical Corp. Petroleum and natural gas are used in its production, sale, and pipeline transportation activities. The business also works with geothermal and new energy sources, as well as the installation of petroleum and petrochemical machinery. Other items produced, sold, stored, and transported by the business include petrochemicals, gas-based chemicals, coal chemicals, and other chemicals. The research, development, and application of technology and information are also activities of Sinopec Corp. The business operates in China, Hong Kong, and the US. Beijing, China is home to Sinopec Corp.

In February 2023, The polyethylene technology of LyondellBasell will once more be licenced to PetroChina Jilin Petrochemical Company for use at their facility in Jilin City, Jilin Province, People's Republic of China. The newly licenced technology will include the industry-leading high-pressure Lupotech process technology from LyondellBasell, which will be applied to both a 300 KTA Tubular line and a 100 KTA Autoclave.

Mitsui & Co Ltd (Mitsui) is a business conglomerate. It provides a wide range of products across a number of industries, including iron and steel, non-ferrous metals, machinery, electronics, chemicals, energy-related commodities, meals & retail, lifestyle, and consumer services. The business engages in a variety of other activities, including arranging financing for clients and suppliers in connection with its trading activities, planning and directing international industrial projects, taking part in financing and investment agreements, assisting in the acquisition of raw materials and equipment, supplying new technologies and manufacturing processes, and organizing the transportation and marketing of finished goods.

In May 2022 In accordance with a stock purchase agreement, Mitsui & Co., Ltd. and FP Corporation have decided to buy all of Lee Soon Seng Plastic Industries Sdn. Bhd.'s shares from SCGM Bhd. LSSPI produces and sells practical food containers mostly throughout Southeast Asia.Graphene Gerdau announced its graphene-infused packaging of Gerdau nail products made at three facilities in Brazil, which are owned by its parent company, namely Gerdau, a major Brazilian steel manufacturer. By using this new packaging, Gerdau intends to reduce its direct plastic consumption by about 25%, or more than 72 tons per year.

This proprietary G2D technology generated the new packaging containing a first-ever polymer masterbatch with graphene dispersed in polyolefins such as polyethylene (PE) and polypropylene (PP), Poly-G PE-07GM at just one percent incorporation level. Therefore, Poly-G can be applied in extrusion processes to produce films, profiles, and sheets.