Market Growth Projections

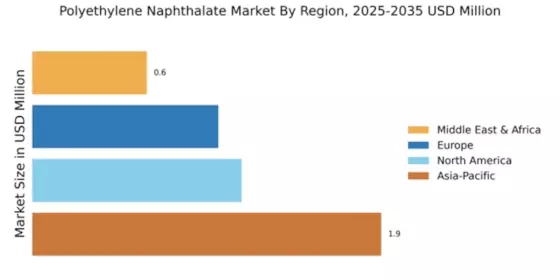

The Global Polyethylene Naphthalate Market Industry is projected to experience substantial growth over the next decade. With a market value anticipated to reach 980.6 USD Million by 2035 and a CAGR of 10.34% from 2025 to 2035, the industry is on a promising trajectory. This growth is driven by various factors, including increased demand for lightweight materials, advancements in manufacturing technologies, and the expansion of applications across multiple sectors. As industries continue to innovate and adapt to changing consumer preferences, the Global Polyethylene Naphthalate Market Industry is likely to thrive, presenting opportunities for stakeholders.

Diverse Applications Across Industries

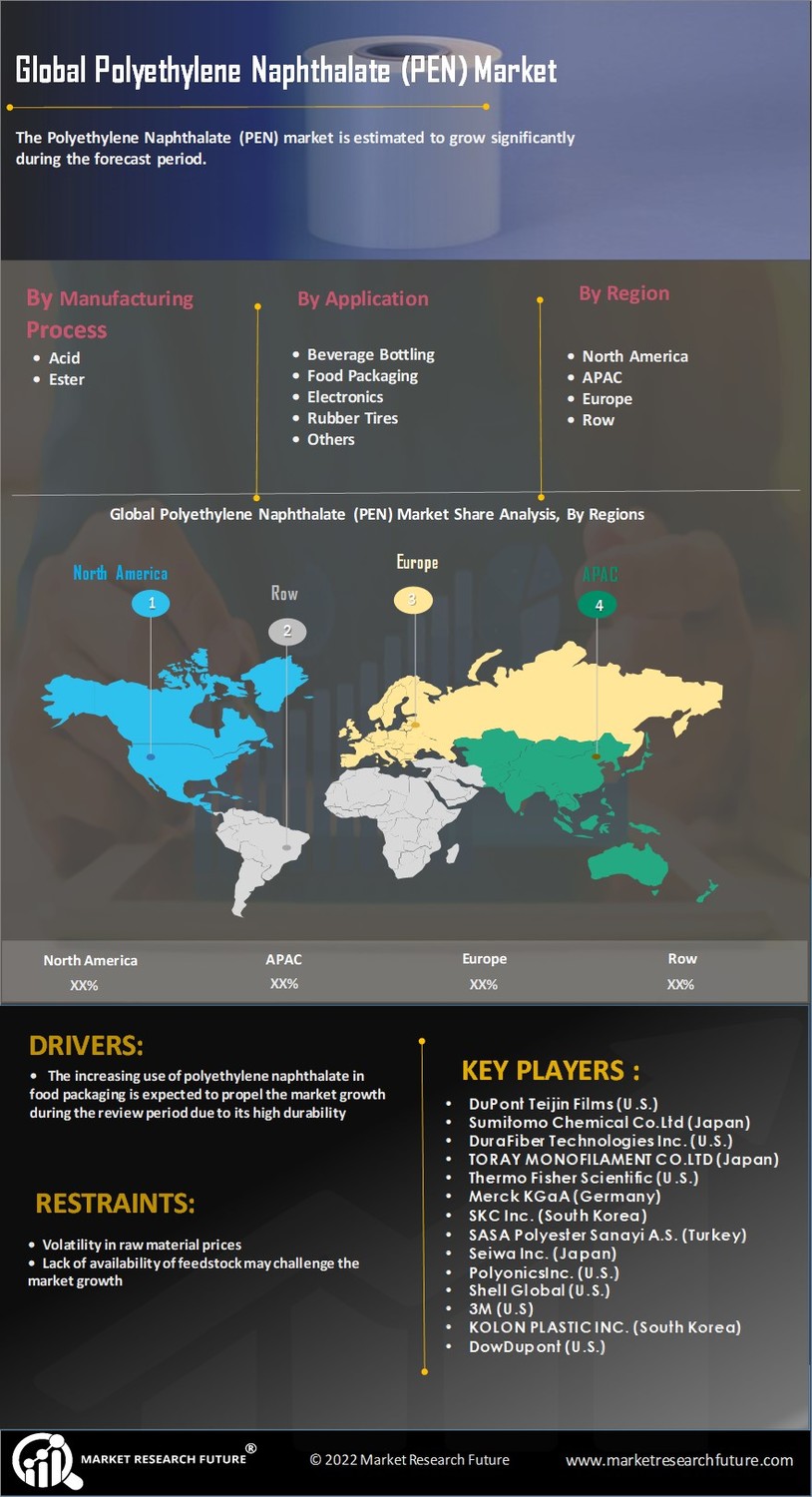

The versatility of polyethylene naphthalate across various industries significantly contributes to the growth of the Global Polyethylene Naphthalate Market Industry. Its applications span from packaging and automotive to textiles and electronics, highlighting its adaptability to meet diverse market needs. This broad applicability ensures a steady demand, as industries increasingly recognize the benefits of using polyethylene naphthalate in their products. The ongoing diversification of applications is likely to sustain market momentum, reinforcing the position of polyethylene naphthalate as a key material in the Global Polyethylene Naphthalate Market Industry.

Rising Demand for Lightweight Materials

The Global Polyethylene Naphthalate Market Industry experiences a surge in demand for lightweight materials across various sectors, particularly in automotive and packaging. As manufacturers seek to enhance fuel efficiency and reduce emissions, the lightweight properties of polyethylene naphthalate become increasingly appealing. This trend is underscored by the automotive industry's commitment to sustainability, with a projected market value of 332.3 USD Million in 2024. The shift towards lightweight materials not only contributes to environmental goals but also aligns with consumer preferences for eco-friendly products, thereby driving growth in the Global Polyethylene Naphthalate Market Industry.

Advancements in Manufacturing Technologies

Technological advancements in the production of polyethylene naphthalate are poised to enhance efficiency and reduce costs within the Global Polyethylene Naphthalate Market Industry. Innovations in polymerization processes and recycling technologies are enabling manufacturers to produce high-quality polyethylene naphthalate more sustainably. These advancements not only improve the material's properties but also contribute to lower production costs, making it more competitive against alternative materials. As the industry embraces these technologies, the potential for market expansion increases, suggesting a promising outlook for the Global Polyethylene Naphthalate Market Industry in the coming years.

Sustainability Initiatives and Regulations

The Global Polyethylene Naphthalate Market Industry is increasingly shaped by sustainability initiatives and regulatory frameworks aimed at reducing plastic waste. Governments worldwide are implementing stringent regulations to promote the use of recyclable and environmentally friendly materials. Polyethylene naphthalate, being recyclable, positions itself as a favorable alternative to traditional plastics. This regulatory push not only enhances the market's appeal but also encourages manufacturers to innovate and adopt sustainable practices. As a result, the Global Polyethylene Naphthalate Market Industry is likely to witness accelerated growth, driven by the alignment of industry practices with global sustainability goals.

Growth in Electronics and Electrical Applications

The Global Polyethylene Naphthalate Market Industry is significantly influenced by the expansion of the electronics and electrical sectors. Polyethylene naphthalate's excellent thermal stability and electrical insulation properties make it an ideal choice for various applications, including flexible printed circuits and insulation materials. As the demand for advanced electronic devices continues to rise, the market is expected to grow substantially. By 2035, the market could reach approximately 980.6 USD Million, reflecting a robust CAGR of 10.34% from 2025 to 2035. This growth is indicative of the increasing reliance on high-performance materials in the electronics industry, further propelling the Global Polyethylene Naphthalate Market Industry.