Growth in End-Use Industries

The expansion of end-use industries such as automotive, electronics, and healthcare is a crucial driver for the PVC Additive Market. The automotive sector, in particular, is experiencing a shift towards lightweight materials, with PVC being favored for its versatility and cost-effectiveness. In 2025, the automotive industry is projected to utilize approximately 20% of the total PVC production, necessitating the use of specialized additives to enhance performance and safety features. Similarly, the electronics industry is increasingly adopting PVC for insulation and protective coatings, further propelling the demand for additives. This growth across various end-use sectors indicates a robust future for the PVC Additive Market, as manufacturers strive to innovate and meet the specific requirements of diverse applications.

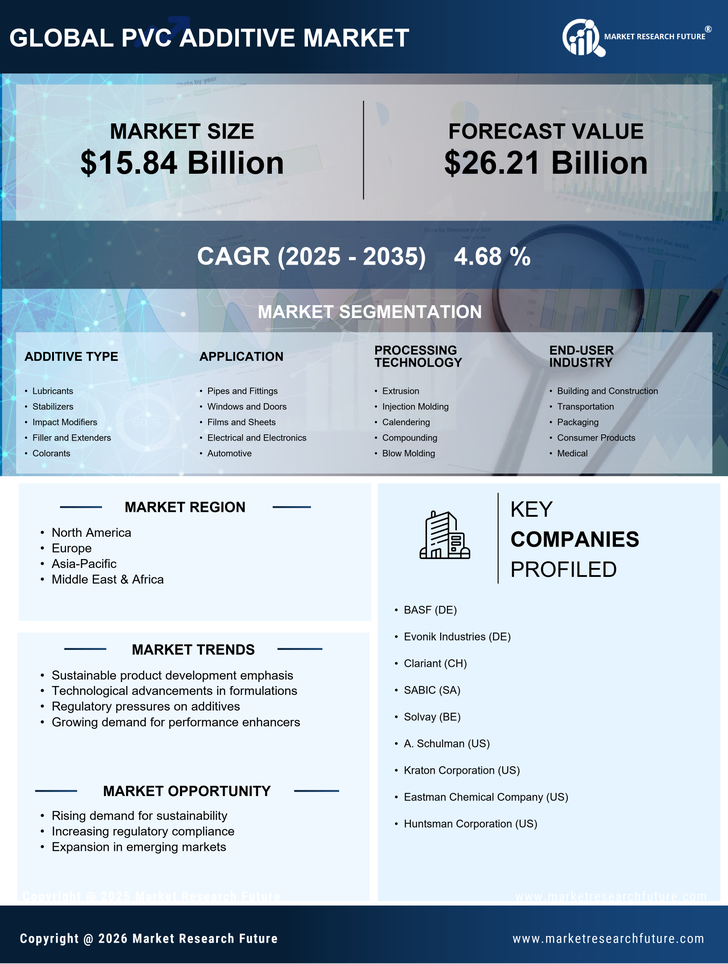

Rising Demand for PVC Products

The increasing demand for PVC products across various sectors, including construction, automotive, and packaging, is a primary driver for the PVC Additive Market. As urbanization accelerates, the construction industry is projected to grow, leading to a heightened need for PVC materials. In 2025, the construction sector is expected to account for a substantial share of the PVC market, with a projected growth rate of approximately 4.5% annually. This surge in demand for PVC products necessitates the use of additives to enhance performance characteristics, such as flexibility, durability, and resistance to environmental factors. Consequently, the PVC Additive Market is likely to experience significant growth as manufacturers seek to meet the evolving needs of various applications.

Stringent Regulatory Frameworks

The PVC Additive Market is significantly influenced by stringent regulatory frameworks aimed at ensuring product safety and environmental protection. Governments worldwide are implementing regulations that govern the use of certain additives, particularly those that may pose health risks. For example, regulations concerning phthalates and heavy metals in PVC products are becoming increasingly stringent. As a result, manufacturers are compelled to invest in compliant additives that meet these regulations, thereby driving demand within the PVC Additive Market. In 2025, it is estimated that compliance-related costs could account for up to 15% of total production costs, prompting companies to seek innovative solutions that adhere to these regulations while maintaining product quality.

Increasing Focus on Sustainability

The PVC Additive Market is witnessing a growing emphasis on sustainability, driven by consumer awareness and corporate responsibility initiatives. Companies are increasingly adopting sustainable practices, including the use of recycled materials and eco-friendly additives. As of 2025, the market for sustainable PVC additives is expected to grow by approximately 5% annually, reflecting a shift in consumer preferences towards environmentally friendly products. This trend is prompting manufacturers to invest in research and development to create additives that not only enhance product performance but also minimize environmental impact. The increasing focus on sustainability is likely to reshape the PVC Additive Market, as stakeholders seek to align with global sustainability goals and meet the demands of environmentally conscious consumers.

Innovations in Additive Technologies

Technological advancements in additive manufacturing are reshaping the PVC Additive Market. Innovations such as nanotechnology and bio-based additives are emerging, offering enhanced performance and sustainability. For instance, the introduction of nanocomposites has shown potential in improving the mechanical properties of PVC, making it more suitable for demanding applications. Furthermore, the market is witnessing a shift towards eco-friendly additives, driven by consumer preferences for sustainable products. As of 2025, the market for bio-based PVC additives is anticipated to grow at a rate of 6%, reflecting a broader trend towards sustainability in the PVC Additive Market. These innovations not only improve product performance but also align with global sustainability goals, thereby attracting investment and interest from various stakeholders.