Technological Advancements in Robotics

Technological advancements play a pivotal role in shaping the Smart Robot Market. Innovations in artificial intelligence, machine learning, and sensor technologies have significantly enhanced the capabilities of smart robots. These advancements enable robots to perform complex tasks, adapt to dynamic environments, and interact more effectively with humans. For example, the integration of AI algorithms allows robots to learn from their experiences, improving their performance over time. The market for smart robots is projected to reach USD 100 billion by 2026, driven by these technological breakthroughs. As companies invest in research and development, the Smart Robot Market is likely to witness the emergence of more sophisticated robotic solutions, catering to a wider array of applications and industries.

Growing Investment in Robotics Startups

The Smart Robot Market is witnessing a surge in investment directed towards robotics startups. Venture capitalists and private equity firms are increasingly recognizing the potential of smart robots to revolutionize various sectors. In 2025, investments in robotics startups are expected to exceed USD 10 billion, reflecting a growing confidence in the market's future. This influx of capital not only accelerates innovation but also fosters the development of cutting-edge technologies that enhance the functionality of smart robots. As startups introduce novel solutions, established companies are compelled to adapt and integrate these innovations into their operations. Consequently, the Smart Robot Market is likely to expand, driven by a vibrant ecosystem of startups pushing the boundaries of what is possible in robotics.

Increased Focus on Safety and Compliance

Safety and compliance have become paramount concerns within the Smart Robot Market. As industries adopt smart robots, ensuring that these systems operate safely alongside human workers is critical. Regulatory bodies are increasingly establishing guidelines and standards for the safe deployment of robots in workplaces. This focus on safety not only protects employees but also enhances the overall acceptance of robotic systems. Companies that prioritize safety measures are likely to gain a competitive edge, as they can assure clients of their commitment to safe operations. The Smart Robot Market is thus expected to grow as organizations invest in safety-compliant robotic solutions, fostering a culture of trust and collaboration between humans and machines.

Rising Demand for Automation in Various Sectors

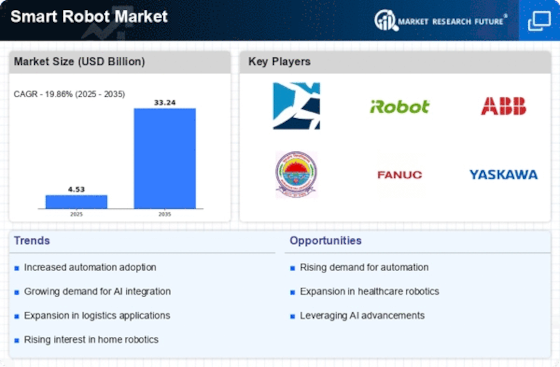

The Smart Robot Market experiences a notable surge in demand for automation across diverse sectors, including manufacturing, healthcare, and logistics. As industries strive for enhanced efficiency and productivity, the integration of smart robots becomes increasingly appealing. For instance, the manufacturing sector has seen a significant increase in the adoption of robotic systems, with a projected growth rate of approximately 15% annually. This trend indicates a shift towards automated solutions that can perform repetitive tasks with precision, thereby reducing operational costs. Furthermore, the healthcare sector is also embracing smart robots for tasks such as surgery assistance and patient care, which further propels the Smart Robot Market. The convergence of these factors suggests a robust growth trajectory for smart robots, as businesses seek to leverage technology to remain competitive.

Expansion of Smart Robotics in Consumer Applications

The Smart Robot Market is experiencing an expansion into consumer applications, driven by increasing consumer interest in automation and smart technologies. Products such as robotic vacuum cleaners, lawn mowers, and personal assistants are gaining traction among consumers, indicating a shift towards smart home solutions. The market for consumer robotics is projected to grow at a compound annual growth rate of 20% over the next five years. This growth is fueled by advancements in technology, making smart robots more accessible and affordable for the average consumer. As the demand for smart home devices rises, the Smart Robot Market is likely to evolve, with manufacturers focusing on creating user-friendly and multifunctional robotic solutions that cater to the needs of everyday consumers.