Rising Industrialization and Urbanization

The Stationary Catalytic System Market is significantly influenced by the ongoing trends of industrialization and urbanization. As countries develop, there is a corresponding increase in industrial activities, which in turn elevates the demand for energy and contributes to higher emissions. The need for effective emission control technologies becomes paramount in urban areas where air quality is a growing concern. In 2025, it is estimated that the market will benefit from a 7% increase in demand due to these factors. Urban centers are increasingly adopting stationary catalytic systems to mitigate the environmental impact of industrial emissions, thereby enhancing the overall sustainability of urban development. This trend underscores the critical role of stationary catalytic systems in addressing the challenges posed by rapid urban growth.

Government Incentives and Support Programs

Government initiatives and support programs are significantly impacting the Stationary Catalytic System Market. Many governments are implementing policies that encourage the adoption of cleaner technologies, including stationary catalytic systems. These initiatives often include financial incentives, tax breaks, and grants aimed at reducing the financial burden on industries transitioning to more sustainable practices. In 2025, it is projected that such government support will contribute to a market growth rate of approximately 8%. This proactive approach by governments not only fosters innovation but also accelerates the deployment of emission control technologies across various sectors. As a result, the Stationary Catalytic System Market is likely to thrive in an environment conducive to sustainable development.

Technological Innovations in Catalytic Systems

Technological advancements are playing a pivotal role in shaping the Stationary Catalytic System Market. Innovations in catalyst formulations and system designs are enhancing the efficiency and effectiveness of these systems. For instance, the introduction of advanced materials and nanotechnology is leading to catalysts that operate at lower temperatures while maintaining high conversion rates. This not only improves performance but also reduces operational costs for industries. By 2025, the market is expected to witness a growth rate of approximately 5% driven by these technological innovations. As industries seek to optimize their processes and reduce emissions, the Stationary Catalytic System Market stands to benefit from the continuous evolution of catalytic technologies.

Increasing Demand for Emission Control Solutions

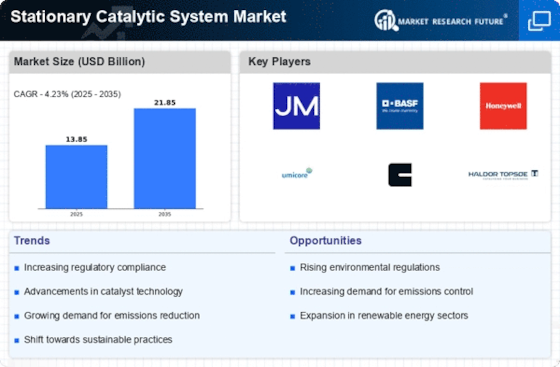

The Stationary Catalytic System Market is experiencing a notable surge in demand for emission control solutions. This trend is largely driven by stringent environmental regulations aimed at reducing air pollution. As industries face mounting pressure to comply with these regulations, the adoption of stationary catalytic systems becomes imperative. In 2025, the market is projected to reach a valuation of approximately USD 5 billion, reflecting a compound annual growth rate of around 6%. This growth is indicative of the increasing recognition of the need for cleaner technologies in various sectors, including power generation and manufacturing. Consequently, the Stationary Catalytic System Market is poised for expansion as companies invest in advanced catalytic technologies to meet compliance requirements.

Growing Awareness of Environmental Sustainability

The Stationary Catalytic System Market is increasingly influenced by the growing awareness of environmental sustainability among consumers and businesses alike. As stakeholders become more conscious of their environmental footprint, there is a heightened demand for technologies that can effectively reduce emissions. This shift in consumer behavior is prompting industries to invest in stationary catalytic systems as part of their sustainability initiatives. In 2025, it is anticipated that the market will experience a growth of around 6% as companies strive to align their operations with sustainable practices. This trend reflects a broader societal movement towards environmental responsibility, further solidifying the importance of stationary catalytic systems in achieving sustainability goals.

.png)