Expansion of Industrial Automation

The expansion of industrial automation is likely to be a key driver for the Thermography Condition Monitoring Equipment Market. As industries adopt automated systems to enhance productivity and reduce labor costs, the need for effective monitoring solutions becomes paramount. Thermography equipment is increasingly integrated into automated systems to provide real-time insights into equipment health and performance. This integration not only aids in predictive maintenance but also enhances overall operational efficiency. Market trends suggest that the automation sector is poised for substantial growth, which may further stimulate the demand for thermography solutions. Consequently, the market for thermography condition monitoring equipment is expected to flourish as automation continues to expand.

Growing Awareness of Energy Efficiency

The growing awareness of energy efficiency and sustainability is emerging as a significant driver for the Thermography Condition Monitoring Equipment Market. Organizations are increasingly focused on reducing energy consumption and minimizing waste, which aligns with global sustainability goals. Thermography plays a vital role in identifying energy losses in electrical systems and thermal insulation, thereby enabling companies to implement corrective measures. Market data indicates that energy audits utilizing thermography can lead to energy savings of up to 20%. As businesses strive to enhance their energy efficiency, the demand for thermography condition monitoring equipment is likely to rise, contributing to market expansion.

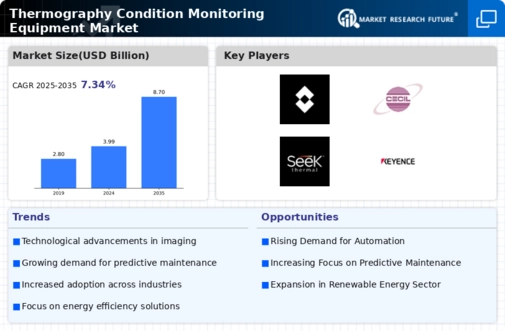

Rising Demand for Predictive Maintenance

The increasing emphasis on predictive maintenance across various sectors appears to be a primary driver for the Thermography Condition Monitoring Equipment Market. Organizations are increasingly recognizing the value of proactive maintenance strategies to minimize downtime and enhance operational efficiency. According to recent data, predictive maintenance can reduce maintenance costs by up to 30%, which is compelling for industries such as manufacturing and energy. This trend is likely to propel the demand for thermography equipment, as it plays a crucial role in identifying potential failures before they occur. As industries strive for operational excellence, the adoption of thermography condition monitoring is expected to rise, thereby expanding the market.

Regulatory Compliance and Safety Standards

The increasing stringency of regulatory compliance and safety standards across industries is a notable driver for the Thermography Condition Monitoring Equipment Market. Organizations are mandated to adhere to safety regulations that necessitate regular monitoring of equipment to prevent accidents and ensure operational safety. For example, industries such as oil and gas, manufacturing, and utilities are required to implement condition monitoring practices to comply with safety regulations. This regulatory landscape is likely to boost the demand for thermography equipment, as it provides a non-invasive method for monitoring equipment health. Consequently, the market is expected to experience growth as companies invest in thermography solutions to meet compliance requirements.

Technological Advancements in Thermography

Technological advancements in thermography equipment are significantly influencing the Thermography Condition Monitoring Equipment Market. Innovations such as enhanced infrared sensors and improved image processing capabilities are making thermography more accessible and effective. For instance, the introduction of portable thermal cameras has broadened the application scope, allowing for real-time monitoring in various environments. Market data suggests that the integration of advanced features, such as wireless connectivity and cloud-based analytics, is likely to enhance user experience and operational efficiency. As these technologies evolve, they may attract a wider range of industries, further driving market growth.