Research Methodology on Machine Condition Monitoring Market

1. Introduction

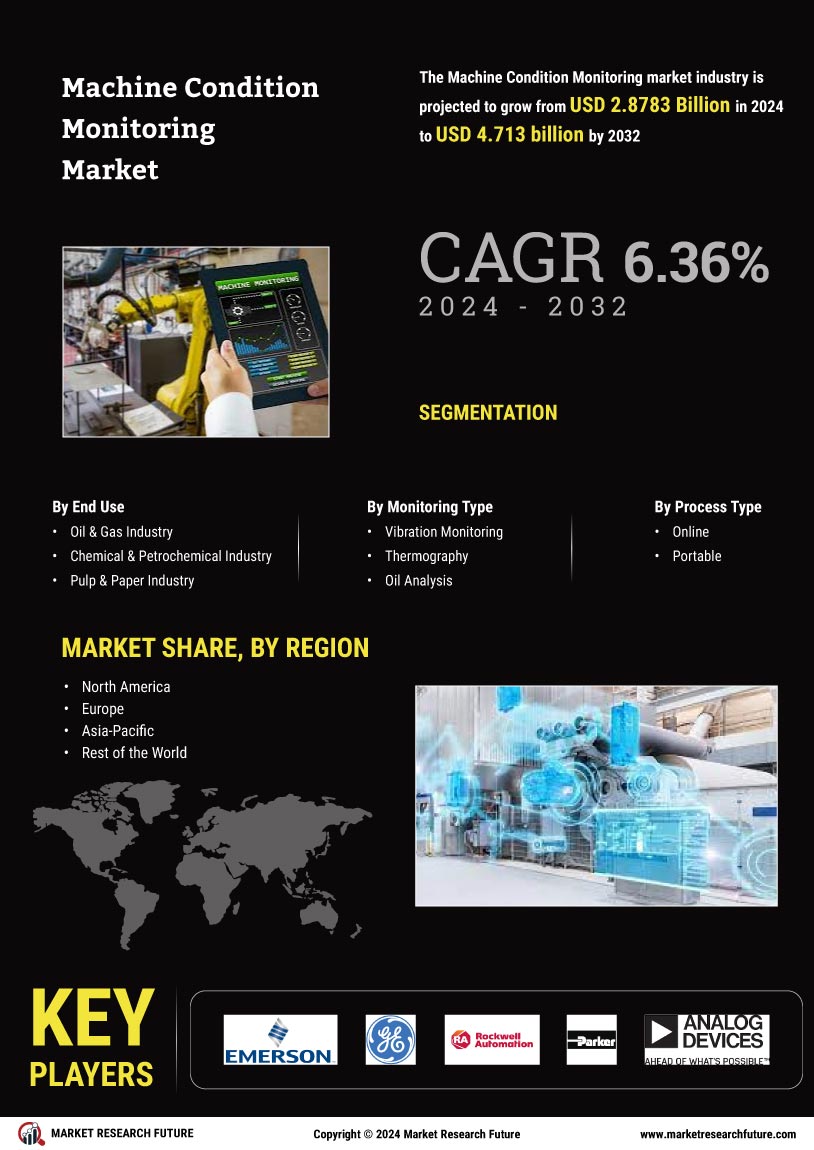

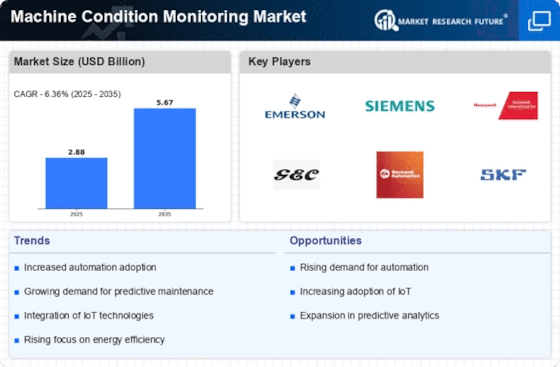

This research aims to provide an all-inclusive assessment of the global Machine Condition Monitoring market in terms of the volume of sales and value of the same in the global market. The research report also gives a thorough account of the technological developments, industry growth drivers and restraints in the global marketplace. The report serves as a comprehensive guide to the global Machine Condition Monitoring market and provides a thorough overview of the competitive landscape of the market along with the forecast for 2023 to 2030.

2. Research Approach and Methodology

The research study has been divided into three phases: primary research, secondary research, and data synthesis. In the first phase, primary research was conducted to understand the current status of the machine condition monitoring market, aiding the analysis of the existing trends and drivers. The primary data was collected through interviews, surveys, and structured questionnaires which covered the key stakeholders such as business leaders, industry experts, and other people associated with the market, which includes manufacturers, distributors, and end users. Additionally, company reports, industry white papers, press releases, and journals were also considered to supplement the primary research.

In secondary research, data was collected by utilizing directories as well as subscriptions to various trade magazines. Multiple sources such as government data, articles, databases, press releases, business directories, company websites, and industry journals were used to gain insights into the market.

The machine condition monitoring market also has a competitive focus in the global arena. The global competitors of major players are competing intensely in the market and have various strategies deployed in the market to sustain their market position. A careful examination and detailed market analysis of the competitive landscape has been undertaken to understand the strategies of the competitors and the market positioning of the key players.

In the data synthesis phase, a blend of the primary and secondary research was analysed together and data was represented in the form of spreadsheets, reports, and fusion charts. All the data gathered was then triangulated to study various parameters such as demand and supply. The industry experts and consultants further provided qualitative inputs about the market during the data triangulation process.

The final stage involved a market assessment that included market segmentation based on market metrics, such as product type, pricing strategy, geography, and application-wise spending, SWOT analysis, Porter's Five Forces Model, technology roadmap, and PESTEL analysis.

3. Market Size Estimation

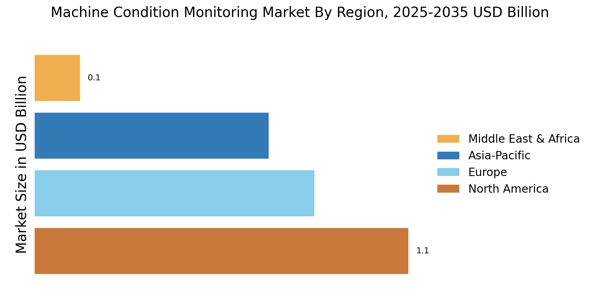

The market estimation was carried out by collecting data on the volume and value from reliable secondary resources such as reports, research papers, financial databases, and surveys. The market estimation was conducted through the top-down & bottom-up approach. Initially, the overall market size was calculated by reviewing the value and volume of the service sold across the globe. However, the regional market size was calculated by adding the value of the services sold in each region. The top-down approach further included the market breakdown in terms of product type, pricing strategy, and geography. The bottom-up approach was adopted to derive the overall market size of the Machine Condition Monitoring market.

4. Data Triangulation

To validate the market size of the Machine Condition Monitoring market, the data collected through various sources were triangulated using the following methods:

- Supply Side: Product type, Pricing Strategy, and Geography

- Demand Side: End-user Analysis and Market Channels

- Scenario Analysis: SME Analysis & DTCA Analysis

5. Pipeline Analysis

The research report presents the market assessment of the pipeline of new products. Under the pipeline analysis, the new product developments, approval pipeline, and clinical trial review were conducted to give a complete picture of the market.

6. Conclusion

The market research study on the Machine Condition Monitoring market has provided a comprehensive analysis of the market, which covers a wide range of supply and demand factors, technological advancements, market value, industry growth, and restraints.

In addition, a complete overview of the competitive landscape and a SWOT analysis of the market has been provided, enabling readers to make the right decision while investing in the Machine Condition Monitoring market. The research report has also considered regional and global developments, trends, competitive landscape, and government regulations, providing a thorough assessment of the global market.