Machine Condition Monitoring Size

Market Size Snapshot

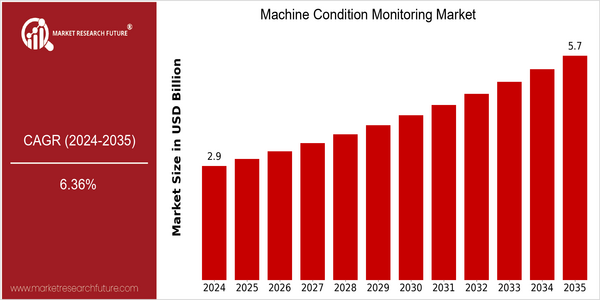

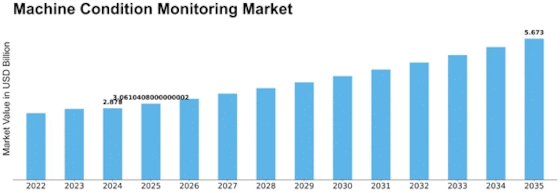

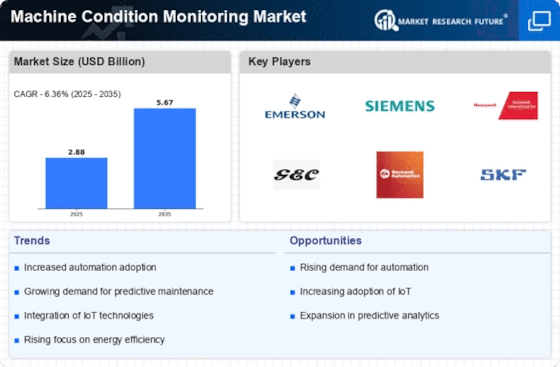

| Year | Value |

|---|---|

| 2024 | USD 2.88 Billion |

| 2035 | USD 5.67 Billion |

| CAGR (2025-2035) | 6.36 % |

Note – Market size depicts the revenue generated over the financial year

The Machine Condition Monitoring Market is poised for a strong growth and is estimated to reach $ 5.67 billion by 2035. This growth will be at a CAGR of 6.36% from 2025 to 2035. The growing adoption of the predictive maintenance strategy across various industries, owing to the need to optimize the performance of the machinery and reduce the downtime, is one of the key factors driving the growth of this market. The advancements in the Internet of Things (IoT) and artificial intelligence (AI) are also enabling more advanced machine condition monitoring solutions, which are facilitating real-time data analysis and enabling improved decision-making. Several players in the machine condition monitoring market, such as SKF, Siemens, and Honeywell, are investing in newer and more advanced machine condition monitoring solutions. Recent collaborations to integrate machine learning into monitoring systems are also expected to optimize the maintenance processes and optimize asset performance. The Machine Condition Monitoring Market is expected to expand significantly in the coming years.

Regional Market Size

Regional Deep Dive

Machine Condition Monitoring Market is experiencing significant growth across all regions, driven by the growing need for operational efficiency and the need for preventive maintenance in the industrial sectors. North America has the highest technology and key players, while Europe is focused on compliance and green initiatives. Asia-Pacific is experiencing rapid industrialization and smart manufacturing investment. The Middle East and Africa are gradually adopting condition monitoring to improve operational reliability. Latin America, although a developing region, is beginning to understand the importance of machine condition monitoring in improving productivity and reducing downtime.

Europe

- The European Union's Green Deal is influencing the market by promoting energy-efficient technologies, leading to increased investments in condition monitoring systems that help reduce energy consumption.

- Companies like SKF and Bosch are innovating with digital twins and real-time monitoring solutions, which are becoming essential for industries aiming to comply with stringent environmental regulations.

Asia Pacific

- Rapid industrialization in countries like China and India is driving demand for condition monitoring solutions, with local companies such as Yokogawa and Mitsubishi Electric investing heavily in smart manufacturing technologies.

- Government initiatives aimed at enhancing manufacturing capabilities, such as 'Made in China 2025', are fostering a conducive environment for the adoption of advanced condition monitoring systems.

Latin America

- Emerging economies in Latin America are beginning to recognize the value of predictive maintenance, with companies like Embraer exploring condition monitoring technologies to enhance operational efficiency.

- Investment in infrastructure and industrial modernization is creating opportunities for condition monitoring solutions, as governments seek to improve productivity in key sectors.

North America

- The integration of IoT and AI technologies in condition monitoring systems is gaining traction, with companies like GE Digital and Siemens leading the charge in developing advanced predictive maintenance solutions.

- Regulatory changes aimed at enhancing workplace safety and operational efficiency are prompting industries to adopt condition monitoring solutions, with organizations such as OSHA advocating for better maintenance practices.

Middle East And Africa

- The oil and gas sector in the Middle East is increasingly adopting condition monitoring technologies to enhance asset reliability, with companies like Schlumberger implementing advanced monitoring solutions.

- Regulatory frameworks are evolving, with governments in the region focusing on improving industrial safety standards, which is expected to drive the adoption of condition monitoring systems.

Did You Know?

“Approximately 70% of machine failures are attributed to a lack of proper maintenance, highlighting the critical role of condition monitoring in preventing costly downtimes.” — International Society of Automation (ISA)

Segmental Market Size

Machine Condition Monitoring Market is experiencing a steady growth, driven by the increasing need for efficient and effective operations across industries. The growing demand for Internet of Things (IoT) solutions for real-time data collection and analysis, and the stringent regulatory framework to enhance the workplace safety and equipment availability, are some of the key factors driving the market. Besides, the growing emphasis on reducing downtime and maintenance costs is also driving the market. In terms of adoption, machine condition monitoring solutions are moving from the pilot phase to large-scale implementations, with notable leaders like Siemens and GE Digital deploying advanced monitoring systems in the manufacturing and energy sectors. The key applications of machine condition monitoring include vibration analysis, thermography, and acoustic monitoring. These solutions are widely used in the aviation and automobile industries to ensure the availability of machines. The rising demand for predictive maintenance is expected to further boost the market growth.

Future Outlook

During the period from 2024 to 2035, the Machine Condition Monitoring market is expected to rise from $2.88 billion to $5.67 billion, registering a CAGR of 6.36%. Its growth will be driven by the increased use of Predictive Maintenance in various industries, such as manufacturing, oil and gas, and transport. In order to reduce downtime and improve operational efficiency, the integration of advanced monitoring tools such as IoT sensors, machine learning, and cloud computing will become more and more common. By 2035, it is expected that more than 60% of industrial companies will adopt some form of condition monitoring, compared to 35% in 2024. This will indicate a significant shift towards data-driven maintenance. Machine learning and data analytics will be the key to a further rise in the Machine Condition Monitoring market. These developments will allow for real-time monitoring and the prediction of equipment failure, which will enable companies to optimize their maintenance schedules and prevent downtime. In addition, the implementation of government initiatives to promote the automation of industries and the reduction of waste will encourage the growth of the market. Rising trends, such as the development of digital twins and the increasing importance of energy efficiency, will also play a significant role in shaping the future of the Machine Condition Monitoring market, ensuring that it remains an integral part of modern industrial activities.

Leave a Comment