Market Share

Introduction: Navigating the Competitive Landscape of Machine Condition Monitoring

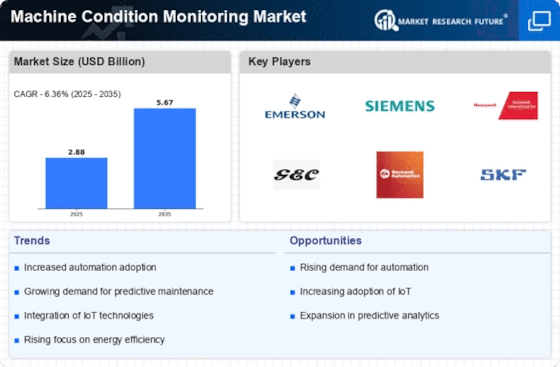

The Machine Condition Monitoring market is evolving, and the market is being driven by the following factors: a quick uptake of new technology, a tightening of the regulatory framework, a growing demand for efficiency and for a sustainable approach to business. These factors are driving a growing competition among the market players, which include the original equipment manufacturers, IT system integrators, and the service companies. These players are using advanced technologies, such as machine learning, IoT, and automation. These differentiators not only improve the predictive maintenance capabilities but also enable real-time data insights, which are critical to operational excellence. These capabilities are attracting new players and are driving the market in the following ways: A growing need for resilience and agility in the organizations.

Competitive Positioning

Full-Suite Integrators

These vendors offer comprehensive solutions that integrate various aspects of machine condition monitoring.

| Vendor | Competitive Edge | Solution Focus | Regional Focus |

|---|---|---|---|

| Rockwell Automation | Strong integration with industrial automation | Industrial IoT and automation solutions | Global |

| GE Digital | Advanced analytics and AI capabilities | Digital industrial solutions | Global |

| Siemens | Robust digital twin technology | Automation and digitalization | Global |

| Emerson Electric | Expertise in process automation | Automation and monitoring solutions | Global |

Specialized Technology Vendors

These vendors focus on niche technologies and solutions tailored for specific monitoring needs.

| Vendor | Competitive Edge | Solution Focus | Regional Focus |

|---|---|---|---|

| PRUFTECHNIK | Leader in alignment and condition monitoring | Vibration analysis and monitoring | Global |

| Vibration Research | Innovative vibration testing solutions | Vibration testing and analysis | Global |

| Digivibe | User-friendly vibration monitoring tools | Vibration monitoring solutions | Global |

| Chauvin Arnoux | Expertise in electrical measurement | Electrical and thermal monitoring | Global |

Infrastructure & Equipment Providers

These vendors supply the hardware and infrastructure necessary for effective condition monitoring.

| Vendor | Competitive Edge | Solution Focus | Regional Focus |

|---|---|---|---|

| Parker Hannifin | Comprehensive fluid power solutions | Condition monitoring equipment | Global |

| Atlas Copco | Innovative air and gas solutions | Monitoring equipment for industrial applications | Global |

| Fluke Corporation | Precision measurement tools | Test and measurement equipment | Global |

| Honeywell International | Diverse industrial solutions | Monitoring and control systems | Global |

| SKF | Expertise in bearings and seals | Condition monitoring solutions | Global |

| National Instruments | Flexible measurement systems | Test and measurement solutions | Global |

| Bentley Systems | Advanced engineering software | Infrastructure engineering solutions | Global |

Emerging Players & Regional Champions

- Vibration Research, Inc., (U.S.A.): This company, which specializes in advanced vibration analysis and monitoring systems, has recently been awarded a contract by a major car manufacturer to monitor their production lines. They are competing with the established companies by offering cheaper and easier to use products.

- Senseye, from the United Kingdom, specializes in the development of machine learning and artificial intelligence-based preventive maintenance software. It recently teamed up with a major energy company to enhance its asset management, and complemented its traditional competitors by providing a cloud-based solution that integrated with the company's existing systems.

- Fluke (US): Known for its portable test and measurement tools, the company has launched a wireless vibration monitoring system, which has recently been installed in a large factory, and which, by offering easy-to-use and integrated solutions, is challenging the established players.

- Monitran (UK): Offers a range of condition monitoring sensors and systems, recently completed a project with a rail operator to monitor track conditions, complementing established vendors by providing specialized solutions tailored for niche markets.

Regional Trends: In 2024, the adoption of condition monitoring technology in Europe and North America will rise considerably, driven by the need for more efficient operation and the need for more accurate maintenance. The trend is towards the integration of IoT and AI, with the focus on cloud-based solutions that can perform real-time data analysis. These new players are able to offer specialized solutions to specific industries and thus compete with the established suppliers.

Collaborations & M&A Movements

- SKF and Siemens have concluded a partnership in order to integrate SKF’s machine condition monitoring into the digital offerings of the Siemens Industry Digital Factory. The aim is to further develop the field of Predictive Maintenance and to strengthen their position in the market for industrial automation.

- Honeywell acquired Intelligrated in early 2024 to expand its machine condition monitoring offerings, thereby increasing its market share in the logistics and supply chain management industry.

- Rockwell Automation and PTC announced a collaboration to develop IoT-enabled condition monitoring systems, which will leverage augmented reality to improve operational efficiency and drive innovation in the manufacturing sector.

Competitive Summary Table

| Capability | Leading Players | Remarks |

|---|---|---|

| Vibration Analysis | SKF, Emerson | In industry, SKF’s vibration analysis tools are widely used, enabling real-time monitoring and prediction of future performance. The latest generation of Emerson’s SmartSignal technology uses advanced algorithms to detect deterioration early and thus enhance operational efficiency. |

| Thermal Imaging | FLIR Systems, Testo | High-resolution thermal cameras are a must for identifying overheated components. They are widely used in electrical and mechanical inspections. Testo's thermographic systems are fully compatible with the company's data loggers, thus enabling maintenance to be planned and controlled more effectively. |

| Ultrasonic Testing | Sonotec, GE Inspection Technologies | Sonotec provides portable ultrasonic testing devices that are favored for their ease of use in field applications. GE Inspection Technologies combines ultrasonic testing with advanced analytics, enabling comprehensive asset health assessments. |

| Oil Analysis | Parker Hannifin, Spectro Scientific | Parker Hannifin's oil analysis services are integrated with their filtration systems, promoting proactive maintenance. Spectro Scientific offers a range of oil analysis kits that are widely used in various industries for condition monitoring. |

| Data Analytics and AI Integration | IBM, Siemens | IBM's Watson IoT platform provides robust data analytics capabilities, enabling predictive maintenance through machine learning. Siemens' MindSphere integrates AI to analyze machine data, offering actionable insights for operational improvements. |

| Cloud-Based Monitoring Solutions | Honeywell, Rockwell Automation | The Honeywell cloud-based remote monitoring systems enable real-time access and real-time data analysis, enhancing decision-making. FactoryTalk Cloud is a comprehensive cloud-based platform for machine condition monitoring. |

Conclusion: Navigating the Machine Monitoring Landscape

As we approach 2024, the Machine Condition Monitoring Market is characterized by intense competition and considerable fragmentation. Across the regions, the trend is toward increasingly advanced solutions, especially in North America and Europe, where the demand for solutions based on artificial intelligence and automation is growing. In order to meet the changing needs of the customer, suppliers must strategically rely on their ability to provide solutions that are sustainable and flexible. The established suppliers are improving their offer through mergers and acquisitions, while the new entrants are focusing on developing agile and real-time data-analytics-based solutions. In the end, it will be the ability to integrate artificial intelligence, automate processes, and deliver sustainable solutions that will determine market leadership and long-term success in this rapidly changing market.

Leave a Comment