Market Analysis

Machine Condition Monitoring Market (Global, 2024)

Introduction

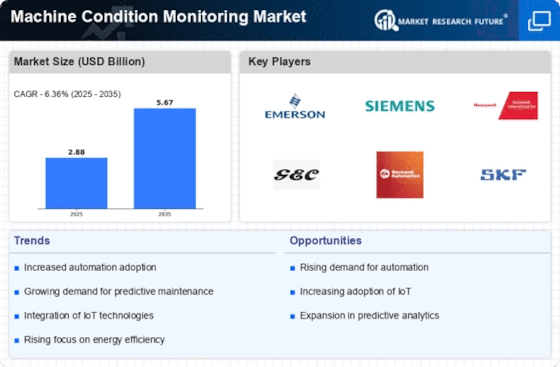

The Machine Condition Monitoring Market is expected to play a major role in the industrial automation, as it is expected to drive the need for better productivity and efficiency in various industries. The growing digitalization of the industry has made the integration of the Internet of Things (IoT), artificial intelligence (AI) and big data analysis into the condition monitoring systems more popular. This combination not only enhances the ability to monitor the health of the machine in real time but also helps to make data-driven decisions and reduce downtime and maintenance costs. Moreover, the growing need for energy efficiency and sustainability has pushed companies to adopt condition monitoring solutions that optimize the use of resources and reduce the impact on the environment. As a result, the Machine Condition Monitoring Market is evolving rapidly, with the emergence of new solutions and the increasing application in manufacturing, energy, transportation and other critical industries.

PESTLE Analysis

- Political

- By 2024, government initiatives to improve productivity and safety are expected to drive the uptake of machine condition monitoring. For example, the US Department of Labor has allocated a budget of 150 million dollars to support advanced manufacturing technology, which includes a component for the development of machine condition monitoring systems. In Europe, new regulations on machinery safety are putting increasing pressure on companies to invest in condition monitoring solutions to avoid fines of up to 500,000 euros for non-compliance.

- Economic

- The economic outlook for 2024 is a rise in the industrial production. The International Monetary Fund expects manufacturing to rise by 3.5%. The growth is likely to boost the investment in condition monitoring systems. The companies will want to optimize their production and reduce the costs of downtime, which can amount to as much as $ 200,000 per hour for critical industries during unplanned outages. The unemployment rate in manufacturing is expected to stabilize at around 4.2 percent, indicating a stable labor market that will support the expansion of production.

- Social

- In 2024 the workforce is increasingly concerned with job security and job satisfaction. Some 78% of manufacturing employees are more likely to prefer companies that have invested in the most advanced technology to ensure their safety and reduce risks. This societal trend is driving companies to adopt machine condition monitoring. These systems not only improve productivity but also contribute to a safe working environment. The growing awareness of mental health in the workplace is driving demand for a technology that can reduce the stress caused by machine failures and maintenance problems.

- Technological

- In 2024, the machine condition monitoring market will be revolutionized by the integration of artificial intelligence and machine learning. In the next five years, companies are expected to invest a total of $ 1.2 billion in smart monitoring solutions that can process huge amounts of data in real time and predict failures with an accuracy of 95%. Furthermore, the proliferation of IoT will lead to an increase of 30 billion in the number of connected machines in the industry, which will lead to more accurate and more complete monitoring and data collection.

- Legal

- In 2024, compliance with international standards such as ISO 55000 for asset management will be of increasing importance for companies. If these standards are not met, companies can be fined up to a million dollars, depending on the severity of the case. In addition, the implementation of data protection regulations such as the General Data Protection Regulation (GDPR) will require companies to ensure compliance with these regulations and this will probably result in additional costs of up to $200,000 for system changes and training.

- Environmental

- In 2024, the industrial environment is subject to an increasingly severe scrutiny, and the regulations relating to the reduction of carbon emissions are becoming increasingly stringent. The European Union has set itself the goal of reducing its carbon emissions by a half by the year 2030. Industry is thus increasingly using condition monitoring systems which optimize energy consumption and reduce waste. The average savings on energy costs, which amount to a reduction of about 20 per cent, amounted in the case of a medium-sized factory to about 100,000 francs per year.

Porter's Five Forces

- Threat of New Entrants

- Barriers to entry: The Machine Condition Monitoring Market has moderate barriers to entry due to the need for specialized technology and expertise. The initial investment is significant, but technological developments and the increasing availability of cloud-based solutions are encouraging new entrants to enter the market. Nonetheless, established companies with strong brand names and customer loyalty present a challenge to new entrants.

- Bargaining Power of Suppliers

- Suppliers of Machine Condition Monitoring generally have a low bargaining power. The market is characterised by a large number of suppliers of individual components and of different monitoring systems. This enables companies to change supplier easily. Furthermore, the technological development and innovation are in constant progress. This means that companies can often find alternative solutions for their needs.

- Bargaining Power of Buyers

- The buyers in this market have high bargaining power, because of the large number of options available to them and the importance of the condition monitoring solution for the efficiency of the production. Customers can easily compare products and services, which makes them price sensitive. Furthermore, large industrial customers often negotiate special terms and conditions, which increases their influence on suppliers.

- Threat of Substitutes

- The threat of substitutes in the machine condition monitoring market is moderate. Manual inspections and preventive maintenance are alternatives to machine condition monitoring systems. But the trend towards automation and preventive maintenance makes condition monitoring systems more attractive. The costs and effectiveness of substitutes can affect the threat of substitutes.

- Competitive Rivalry

- Competition in the Machine Condition Monitoring Market is high, owing to the presence of a large number of players and the rapid pace of technological development. The companies are trying to differentiate their products and services from those of their competitors by constantly launching new products. This is leading to aggressive marketing and price competition. The need to improve and meet the requirements of the customers is further intensifying the competition among the companies.

SWOT Analysis

Strengths

- Increasing demand for predictive maintenance solutions to reduce downtime.

- Advancements in IoT and AI technologies enhancing monitoring capabilities.

- Growing awareness of the importance of machine health in operational efficiency.

Weaknesses

- High initial investment costs for advanced monitoring systems.

- Complexity in integrating new technologies with existing systems.

- Limited awareness and understanding of machine condition monitoring among smaller enterprises.

Opportunities

- Expansion of the market in emerging economies with industrial growth.

- Development of cost-effective solutions for small and medium-sized enterprises.

- Rising focus on sustainability and energy efficiency driving demand for monitoring solutions.

Threats

- Rapid technological changes leading to obsolescence of current solutions.

- Intense competition from established players and new entrants.

- Potential cybersecurity risks associated with connected monitoring systems.

Summary

The Machine Condition Monitoring Market is characterized by strong growth by 2024, which is mainly driven by the technological advancement and the increasing demand for the predictive maintenance. However, the high cost and the complexity of the integration may hinder the growth of the market, especially in the small and medium-sized companies. Opportunities are available in the emerging markets and in the development of affordable solutions. Threats are competition and the security risk.

Leave a Comment