Market Trends

Introduction

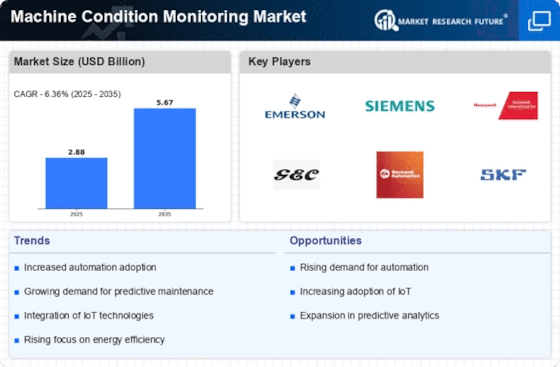

By the time 2024 arrives, the Machine Condition Monitoring market is undergoing a major transformation driven by a number of macro-economic factors. The rapid technological advances, particularly in IoT and artificial intelligence, are enabling the real-time monitoring and data analysis of machines. The growing regulatory pressure to improve the operational safety and efficiency of industrial plants is driving the industries to adopt more sophisticated condition monitoring solutions. Furthermore, the shift in the consumers’ attitudes towards the sustainable development and the operational transparency is influencing the companies to invest in condition monitoring. The trends are strategically important for the Machine Condition Monitoring market players, as they not only improve the operational efficiency, but also mitigate the risks associated with machine failures. The end result is a stronger competitiveness in the increasingly complex market environment.

Top Trends

-

Integration of IoT Technologies

In the field of machinery condition monitoring, the IoT is revolutionizing data collection and analysis. The IoT is being used to enhance the capability of predicting when equipment will fail. GE Digital has used the IoT to reduce downtime by a staggering 20 percent. This trend will improve the efficiency of operations and reduce maintenance costs. Real-time monitoring will become the norm, leading to smarter manufacturing. -

AI and Machine Learning Adoption

Artificial intelligence and machine learning are being increasingly used to analyse the vast amounts of data collected from condition monitoring. For example, Rockwell has introduced artificial intelligence to improve the accuracy of its fault detection by a third. This trend is improving the reliability of predictive maintenance, enabling companies to anticipate breakdowns. And the next stage may be towards more self-learning systems, which require less human intervention. -

Cloud-Based Solutions

The use of cloud-based data analysis is becoming indispensable. As a result, cloud-based platforms such as those offered by companies such as Siemens are enabling remote access to machine data, thus facilitating both collaboration and decision-making. It is expected that this new approach will increase the security of the data and its scalability, thus enabling companies to respond quickly to changing operational requirements. The trend towards cloud-based data analysis is therefore set to continue, enabling real-time data to be gathered and analysed in future. -

Increased Focus on Sustainability

Machine condition monitoring is becoming a key driver of energy and resource conservation, with companies striving to reduce their energy consumption and waste. SKF has developed a range of solutions that can optimize machine performance and minimize the environment’s impact. This is not only a response to regulatory requirements, but also a trend driven by consumers’ desire to be more sustainable. Future developments may well include more sustainable monitoring technology. -

Enhanced User Interfaces and Visualization Tools

The new tools of data representation are constantly evolving and are increasingly becoming more intuitive. Firms like Honeywell International are investing in advanced dashboards that make it easier for operators to understand the data. This trend is fostering greater engagement and better decision-making, which in turn leads to faster maintenance response times. There are also a number of developments in the field of augmented reality that could be used for real-time monitoring. -

Regulatory Compliance and Standards

Regulations increasingly influence the practice of condition monitoring. Governments are imposing stricter regulations on the safety and performance of machines, which lead to the need for monitoring solutions. In particular, the introduction of ISO standards for predictive maintenance is a driving force for the market. The trend is to maintain the efficiency of the plant and avoid penalties. -

Growth of Predictive Maintenance Services

Predictive maintenance is gaining in importance, as companies seek to minimize unplanned downtime. National Instruments has seen a 25% increase in the number of requests for its solutions in this field. The new trend is affecting service agreements. More and more companies are choosing a subscription-based model. This may lead to the development of more sophisticated tools for predicting failures. -

Collaboration with Technology Startups

The companies that have already established themselves in this field are increasingly collaborating with technology start-ups. For example, Parker Hannifin has teamed up with start-ups to develop cutting-edge sensors. This trend accelerates the development of new solutions and increases the competitive advantage. These future collaborations could lead to a breakthrough in terms of monitoring and data analysis. -

Remote Monitoring Capabilities

The possibility of remote control is becoming essential, especially after the COVID-19 epidemic. Companies like Fluke have developed solutions that allow for the remote monitoring of equipment. This trend increases the safety of operations and the flexibility of the organization, enabling it to continue to operate in the event of a disruption. And in the future, the trend may lead to more powerful remote diagnostic tools. -

Integration of Augmented Reality (AR)

Combined with the augmented reality (AR) of the augmented reality (AR) of the augmented reality (AR) of the augmented reality (AR) of the augmented reality (AR) of the augmented reality (AR) of the augmented reality (AR)) of the augmented reality (AR) in the machine state monitoring, the maintenance processes are improved. Emerson Electric is already exploring applications that will provide technicians with real-time data overlays during inspections. This trend increases the accuracy of the work and reduces the time needed to train new employees. In the future, it is likely that the augmented reality (AR) will become a standard tool for maintenance.

Conclusion: Navigating the Machine Monitoring Landscape

In 2024, the Machine Condition Monitoring market is characterized by a highly competitive environment and significant fragmentation, with both established and new companies fighting for market share. In terms of geographical trends, the emphasis is on advanced technology, particularly in North America and Europe, where demand for AI-based solutions and automation is growing rapidly. Strategically, companies need to exploit their flexibility and flexibility in order to meet evolving customer expectations. As a result, established companies are enhancing their offerings through mergers and acquisitions, while new companies are focusing on agile solutions that are based on real-time data analysis. In the long run, the ability to integrate AI, automate processes and provide sustainable practices will be the decisive factor in determining market leadership and long-term success in this rapidly changing environment.

Leave a Comment