Growing Demand in Emerging Markets

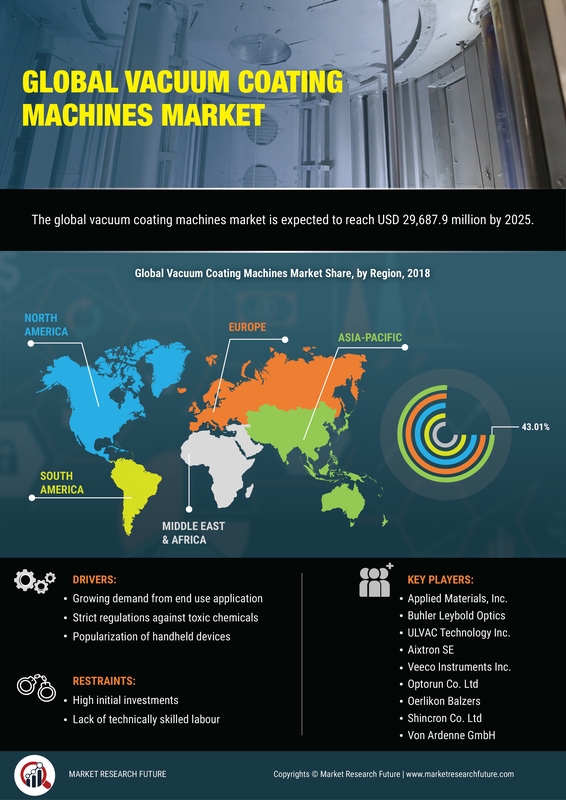

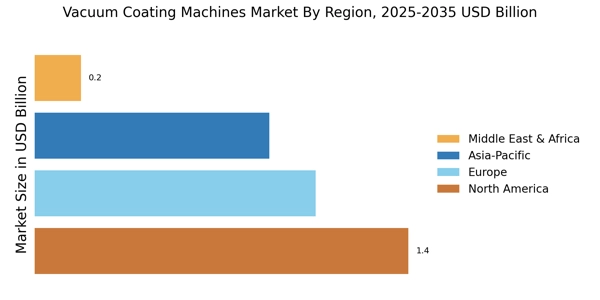

The Vacuum Coating Machines Market is witnessing a notable increase in demand from emerging markets, particularly in Asia-Pacific and Latin America. Rapid industrialization and urbanization in these regions are driving the need for advanced manufacturing technologies, including vacuum coating machines. As local industries expand, there is a growing requirement for high-quality coatings in sectors such as electronics, automotive, and packaging. Market data indicates that the Asia-Pacific region alone is expected to account for over 40% of the total market share by 2026, reflecting the significant growth potential in these areas. This trend suggests that manufacturers are likely to invest in vacuum coating technologies to enhance their competitive edge in these burgeoning markets.

Rising Applications in Various Industries

The Vacuum Coating Machines Market is expanding due to the rising applications of vacuum coating technologies across various sectors. Industries such as electronics, automotive, and optics are increasingly utilizing vacuum coatings for their products, which enhances performance and longevity. For instance, the electronics sector employs vacuum coatings for semiconductors and displays, while the automotive industry uses them for decorative and protective finishes. This diversification of applications is expected to drive market growth, with projections indicating a potential increase in market size by approximately 5% annually over the next few years. As more industries recognize the benefits of vacuum coating, the demand for specialized machines tailored to specific applications is likely to rise.

Sustainability Initiatives in Manufacturing

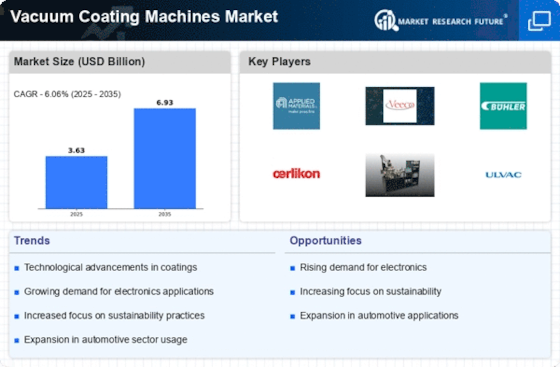

The Vacuum Coating Machines Market is increasingly influenced by sustainability initiatives that aim to reduce environmental impact. Manufacturers are under pressure to adopt eco-friendly practices, and vacuum coating technologies are well-positioned to meet these demands. The use of vacuum coating machines can minimize waste and energy consumption, aligning with global sustainability goals. Furthermore, the shift towards renewable energy sources and sustainable materials is driving the need for advanced coating solutions that enhance product durability and performance. As industries strive to meet regulatory requirements and consumer expectations for sustainability, the vacuum coating machines market is likely to see a rise in demand for machines that support these initiatives, potentially leading to a market growth rate of around 7% in the coming years.

Increased Investment in Research and Development

The Vacuum Coating Machines Market is benefiting from increased investment in research and development (R&D) activities. Companies are allocating significant resources to innovate and improve vacuum coating technologies, aiming to enhance performance and reduce costs. This focus on R&D is crucial as it leads to the development of new materials and processes that can further expand the applications of vacuum coatings. Recent trends suggest that R&D spending in the vacuum coating sector could increase by 10% annually, reflecting the industry's commitment to innovation. As manufacturers strive to stay competitive, the emphasis on R&D is likely to result in the introduction of advanced vacuum coating machines that meet the evolving needs of various industries.

Technological Advancements in Vacuum Coating Machines

The Vacuum Coating Machines Market is experiencing a surge in technological advancements that enhance the efficiency and effectiveness of coating processes. Innovations such as atomic layer deposition and magnetron sputtering are becoming increasingly prevalent, allowing for the production of thinner and more uniform coatings. These advancements not only improve the quality of the final products but also reduce material waste, which is a critical factor in today's manufacturing landscape. According to recent data, the market for vacuum coating machines is projected to grow at a compound annual growth rate of approximately 6.5% over the next five years, driven by these technological improvements. As manufacturers seek to optimize their production capabilities, the demand for advanced vacuum coating machines is likely to increase, further propelling the market forward.