Diverse Applications Across Industries

The versatility of vapor blasting technology is a key driver in the Vapor Blasting Equipment Market. This method finds applications in various sectors, including automotive, aerospace, and manufacturing. For instance, in the automotive industry, vapor blasting is utilized for cleaning engine components and restoring surfaces without damaging the underlying material. The aerospace sector benefits from vapor blasting for precision cleaning of aircraft parts, ensuring safety and performance. As industries increasingly recognize the advantages of vapor blasting, the demand for specialized equipment is expected to rise. This trend indicates a robust growth trajectory for the market, as companies seek to leverage the unique benefits of vapor blasting across diverse applications.

Sustainability and Environmental Regulations

The increasing emphasis on sustainability is a pivotal driver in the Vapor Blasting Equipment Market. As environmental regulations become more stringent, industries are compelled to adopt eco-friendly practices. Vapor blasting, known for its minimal environmental impact compared to traditional methods, aligns well with these regulations. The process utilizes water and biodegradable media, significantly reducing airborne dust and hazardous waste. Consequently, companies are investing in vapor blasting equipment to comply with environmental standards while enhancing their corporate social responsibility profiles. This shift not only meets regulatory requirements but also appeals to environmentally conscious consumers, potentially expanding market opportunities.

Cost-Effectiveness and Operational Efficiency

Cost-effectiveness is a compelling driver in the Vapor Blasting Equipment Market. The initial investment in vapor blasting equipment is often offset by the long-term savings achieved through reduced material consumption and lower labor costs. The efficiency of vapor blasting processes minimizes the need for extensive post-treatment, thereby streamlining operations. Additionally, the ability to reuse blasting media contributes to cost savings, making vapor blasting an attractive option for many businesses. As companies seek to optimize their operational expenditures while maintaining high-quality standards, the adoption of vapor blasting technology is likely to increase, further propelling market growth.

Growing Demand for Surface Preparation Solutions

The demand for effective surface preparation solutions is a significant driver in the Vapor Blasting Equipment Market. Industries are increasingly recognizing the importance of surface treatment in enhancing product quality and longevity. Vapor blasting provides a superior finish, improving adhesion for coatings and paints, which is crucial in sectors such as construction and manufacturing. As companies strive for higher quality standards and durability in their products, the need for advanced surface preparation techniques is likely to grow. This trend suggests a promising outlook for the vapor blasting equipment market, as businesses invest in technologies that ensure optimal surface conditions.

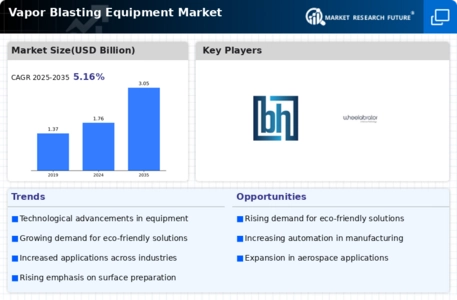

Technological Advancements in Vapor Blasting Equipment

The Vapor Blasting Equipment Market is experiencing a surge in technological advancements that enhance efficiency and effectiveness. Innovations such as automated systems and improved nozzle designs are streamlining operations, thereby reducing labor costs and increasing productivity. The integration of smart technologies, including IoT capabilities, allows for real-time monitoring and data collection, which can lead to better decision-making and maintenance practices. As manufacturers continue to invest in research and development, the market is likely to see a rise in sophisticated equipment that meets the evolving needs of various industries. This trend not only boosts operational efficiency but also positions companies to remain competitive in a rapidly changing landscape.

.png)