Emerging Markets and Industrialization

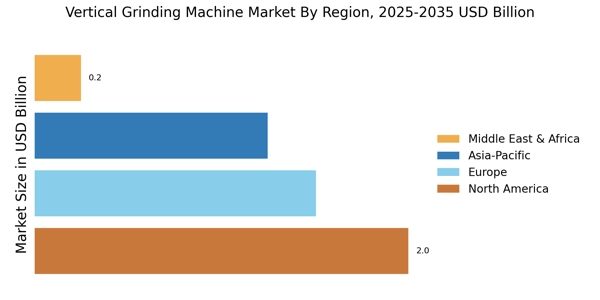

Emerging markets are playing a crucial role in the growth of the Vertical Grinding Machine Market, driven by rapid industrialization and infrastructure development. Countries in Asia and South America are investing heavily in manufacturing capabilities, leading to an increased demand for advanced machining solutions. Data suggests that the manufacturing sector in these regions is expected to grow by 7% annually, creating a substantial market for vertical grinding machines. As these economies continue to develop, the demand for efficient and high-quality grinding solutions is likely to expand, presenting opportunities for market players.

Sustainability Focus in Manufacturing Processes

The Vertical Grinding Machine Market is witnessing a growing emphasis on sustainability, as manufacturers strive to reduce their environmental footprint. This focus on eco-friendly practices includes the development of energy-efficient machines and the use of recyclable materials in manufacturing. Recent studies suggest that companies adopting sustainable practices can reduce operational costs by approximately 15%. As industries become more environmentally conscious, the demand for vertical grinding machines that align with sustainability goals is likely to increase, thereby driving market expansion.

Rising Demand from Aerospace and Automotive Sectors

The aerospace and automotive sectors are significant contributors to the Vertical Grinding Machine Market, as these industries require high-precision components. The increasing production of aircraft and vehicles necessitates advanced grinding solutions that can deliver the required tolerances and surface finishes. Market analysis indicates that the aerospace sector alone is projected to grow at a CAGR of 5% over the next five years, further fueling the demand for vertical grinding machines. As these sectors expand, the need for reliable and efficient grinding solutions is expected to rise, positively impacting market dynamics.

Customization Demand in Vertical Grinding Machine Market

Customization is a pivotal driver in the Vertical Grinding Machine Market, as manufacturers increasingly seek tailored solutions to meet specific production needs. The ability to modify grinding machines to accommodate various materials and sizes is becoming essential. This trend is particularly evident in sectors like medical device manufacturing and precision engineering, where unique specifications are commonplace. Market data indicates that customized machines can lead to a 20% increase in productivity, as they are designed to handle specific tasks more efficiently. Consequently, the demand for customizable vertical grinding machines is expected to propel market growth.

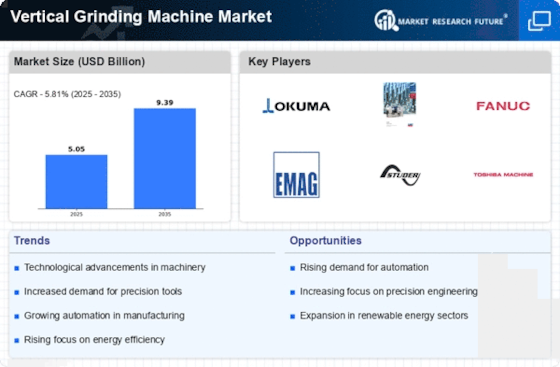

Technological Advancements in Vertical Grinding Machines

The Vertical Grinding Machine Market is experiencing a surge in technological advancements that enhance precision and efficiency. Innovations such as CNC (Computer Numerical Control) systems and automation are becoming increasingly prevalent. These technologies allow for higher accuracy in machining processes, which is crucial for industries such as aerospace and automotive. According to recent data, the integration of advanced software solutions has improved operational efficiency by up to 30%. As manufacturers seek to optimize production capabilities, the demand for technologically advanced vertical grinding machines is likely to rise, driving growth in the market.