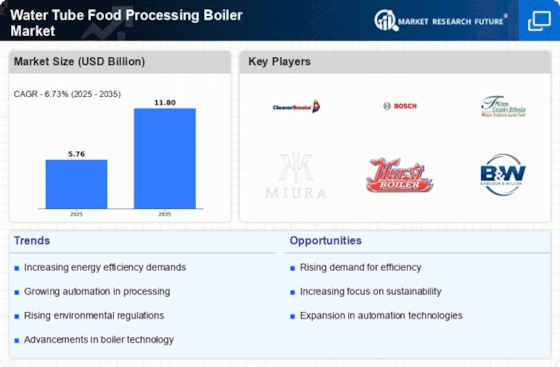

Focus on Energy Efficiency

The focus on energy efficiency is a critical driver for the Water Tube Food Processing Boiler Market. With rising energy costs and increasing environmental regulations, food processors are under pressure to reduce their energy consumption. Water tube boilers are known for their high efficiency and lower emissions compared to traditional fire tube boilers. According to recent studies, energy-efficient boilers can reduce fuel consumption by up to 20%, translating into significant cost savings for manufacturers. As the food processing sector strives to meet sustainability targets, the adoption of energy-efficient water tube boilers is likely to accelerate. This trend not only helps in reducing operational costs but also enhances the overall sustainability profile of food processing operations, making it a key factor in the market's growth.

Rising Demand for Processed Food

The increasing demand for processed food products is a primary driver for the Water Tube Food Processing Boiler Market. As consumer preferences shift towards convenience and ready-to-eat meals, food manufacturers are compelled to enhance their production capabilities. This trend is reflected in the projected growth of the processed food sector, which is expected to reach a valuation of over 3 trillion USD by 2025. Consequently, the need for efficient and reliable heating solutions, such as water tube boilers, becomes paramount. These boilers offer superior thermal efficiency and faster heating times, which are essential for meeting the high production demands of the food processing industry. As a result, manufacturers are likely to invest in advanced water tube boiler systems to optimize their operations and maintain competitiveness in the market.

Expansion of Food Processing Industries

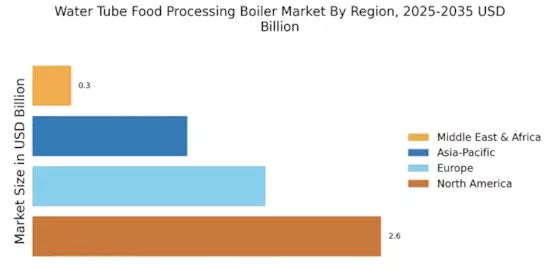

The expansion of food processing industries is a notable driver for the Water Tube Food Processing Boiler Market. As economies develop and urbanization increases, there is a corresponding rise in food processing activities. This expansion is particularly evident in emerging markets, where the demand for processed food is surging. The food processing industry is projected to grow at a rate of approximately 4% annually, creating a substantial need for efficient heating solutions. Water tube boilers, known for their ability to handle large volumes of steam and high-pressure applications, are becoming increasingly essential in these expanding facilities. As food processors invest in new technologies and infrastructure to meet growing consumer demands, the water tube boiler market is likely to experience robust growth, driven by this industry expansion.

Regulatory Compliance and Safety Standards

Regulatory compliance and safety standards are increasingly shaping the Water Tube Food Processing Boiler Market. Governments and regulatory bodies are implementing stringent safety and environmental regulations that food manufacturers must adhere to. Compliance with these regulations often necessitates the use of advanced boiler systems that meet specific safety and efficiency criteria. Water tube boilers, with their robust design and safety features, are well-suited to meet these requirements. The market is witnessing a shift towards boilers that not only comply with existing regulations but also anticipate future standards. This proactive approach is likely to drive investments in modern water tube boiler systems, as manufacturers seek to avoid penalties and ensure safe operations. As a result, regulatory compliance is expected to remain a significant driver of market growth.

Technological Advancements in Boiler Design

Technological advancements in boiler design are significantly influencing the Water Tube Food Processing Boiler Market. Innovations such as enhanced heat transfer mechanisms and improved fuel efficiency are making water tube boilers more attractive to food processors. For instance, the integration of smart technology allows for real-time monitoring and control of boiler operations, leading to increased efficiency and reduced operational costs. The market for industrial boilers is projected to grow at a CAGR of approximately 5% through 2025, driven by these technological improvements. Furthermore, the development of eco-friendly boiler options, which utilize renewable energy sources, aligns with the industry's sustainability goals. As food manufacturers seek to modernize their facilities, the demand for advanced water tube boilers is expected to rise, thereby propelling market growth.