Rising Demand for Fuel Efficiency

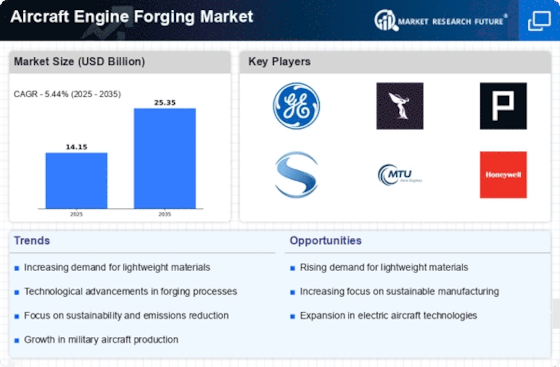

The aircraft engine forging Market is experiencing a notable surge in demand for fuel-efficient engines. As airlines and manufacturers strive to reduce operational costs and environmental impact, the focus on lightweight and durable forged components has intensified. Recent data indicates that fuel-efficient engines can reduce fuel consumption by up to 15%, which is a significant incentive for stakeholders. This trend is likely to drive investments in advanced forging technologies, enabling the production of components that meet stringent performance standards. Consequently, the Aircraft Engine Forging Market is poised for growth as manufacturers adapt to these evolving demands.

Increased Aircraft Production Rates

The Aircraft Engine Forging Market is benefiting from the rising production rates of commercial and military aircraft. With the demand for air travel increasing, manufacturers are ramping up production to meet this need. Reports suggest that aircraft production is expected to grow by approximately 4% annually over the next decade. This growth necessitates a corresponding increase in the supply of high-quality forged engine components, which are critical for performance and safety. As a result, the Aircraft Engine Forging Market is likely to see heightened activity as suppliers align their capabilities with the expanding production landscape.

Growing Focus on Sustainable Practices

Sustainability is becoming a central theme in the Aircraft Engine Forging Market. Manufacturers are increasingly adopting eco-friendly practices, such as using recycled materials and reducing energy consumption during the forging process. This shift is driven by both regulatory pressures and consumer preferences for greener aviation solutions. Data suggests that the adoption of sustainable practices can lead to a reduction in carbon emissions by up to 30% in the manufacturing phase. As the industry moves towards more sustainable operations, the Aircraft Engine Forging Market is likely to evolve, with a focus on innovations that align with environmental goals.

Regulatory Compliance and Safety Standards

The Aircraft Engine Forging Market is significantly influenced by stringent regulatory compliance and safety standards. Governments and aviation authorities impose rigorous requirements to ensure the safety and reliability of aircraft engines. This has led to an increased emphasis on the quality of forged components, as they must meet specific performance criteria. Manufacturers are investing in quality assurance processes and certifications to comply with these regulations. As safety remains a top priority in aviation, the Aircraft Engine Forging Market is likely to see sustained demand for high-quality, compliant forged components that meet or exceed industry standards.

Technological Innovations in Forging Processes

Technological advancements are playing a pivotal role in shaping the Aircraft Engine Forging Market. Innovations such as precision forging and additive manufacturing are enhancing the quality and efficiency of forged components. These technologies allow for the production of complex geometries and improved material properties, which are essential for modern aircraft engines. The integration of automation and digitalization in forging processes is also streamlining operations, reducing lead times, and minimizing waste. As these technologies continue to evolve, they are expected to drive competitiveness within the Aircraft Engine Forging Market, fostering a landscape of continuous improvement.