Research Methodology on Automotive Powertrain Systems Market

1. Introduction

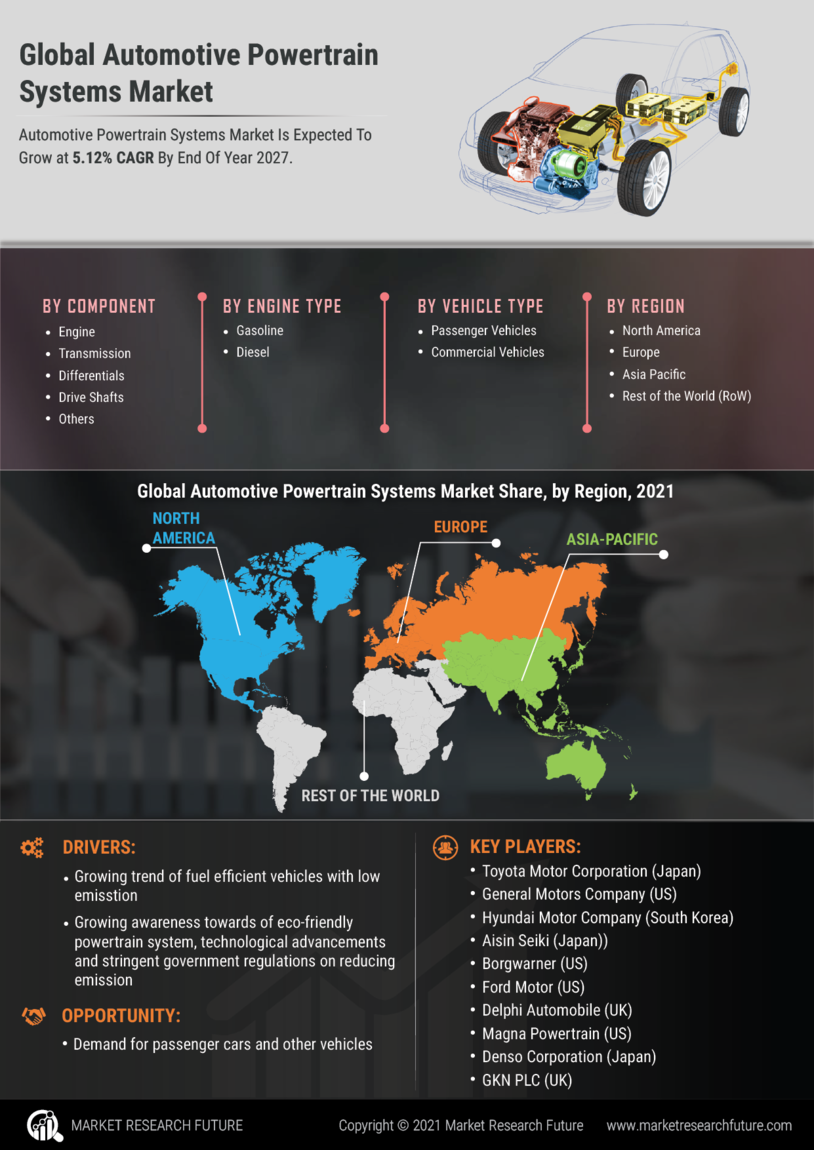

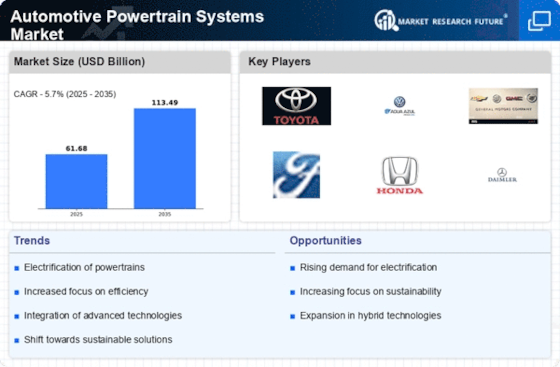

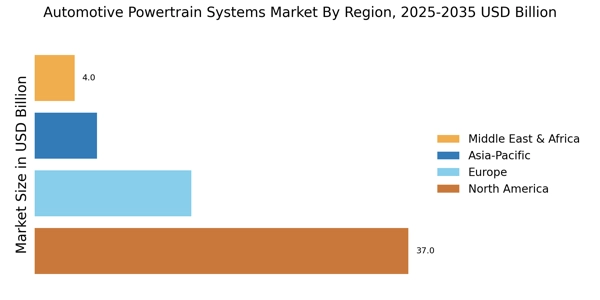

This research aims to provide an in-depth analysis of the automotive powertrain systems market by examining its current market size, market trends, and industry growth prospects. The research seeks to provide a comprehensive evaluation of the market size, market trends, and market dynamics of the automotive powertrain systems market. It also seeks to provide an in-depth analysis of the impact of the current market trends in the industry, as well as to gain insights into the potential growth prospects of the automotive powertrain systems market in the coming years.

2. Research Design

The research design follows a quantitative and qualitative approach to assess the market size, market trends, and industry growth prospects of the automotive powertrain systems market.

1. Quantitative Data Collection

The quantitative data collection approach uses both primary and secondary sources to collect relevant market data. Primary data is collected using detailed interviews with industry experts, who were asked to provide in-depth insights into the current market size, market trends, and industry growth prospects of the automotive powertrain systems market. Secondary research is conducted by collecting data from reliable and authoritative sources such as industry magazines, reports, and other relevant industry studies.

2. Qualitative Data Collection

The qualitative data collection approach is used to assess the impact of the current market trends on the automotive powertrain systems market and to gauge the potential growth prospects of the automotive powertrain systems market in the coming years. Data was collected from various industry experts and was analyzed to gain insights into the industry.

3. Market Forecasting

Market forecasting is undertaken using market analytics software (MAF), which is used to generate quantitative and qualitative market forecasts. The forecasts are also generated using a combination of historical market data, industry expert opinions, and other related quantitative data sources.

4. Data Analysis

The collected data is then subjected to rigorous analysis to gain in-depth insights into the current market size, market trends, and industry growth prospects of the automotive powertrain systems market. Statistical tools such as regression, correlation, and time series analysis are used to assess the current market trends and to generate quantitative forecasts.

Further, descriptive and exploratory data analysis techniques are used to gain insights into the potential growth prospects of the automotive powertrain systems market in the coming years.

Conclusion

This research provides a comprehensive analysis of the automotive powertrain systems market by assessing its current market size, market trends, and industry growth prospects. The research also provides detailed forecasts and market dynamics which could be used to gain insights into the industry and its potential growth prospects in the coming years. The research methodology used ensured that the data collected was of high quality, reliable, and comprehensive.