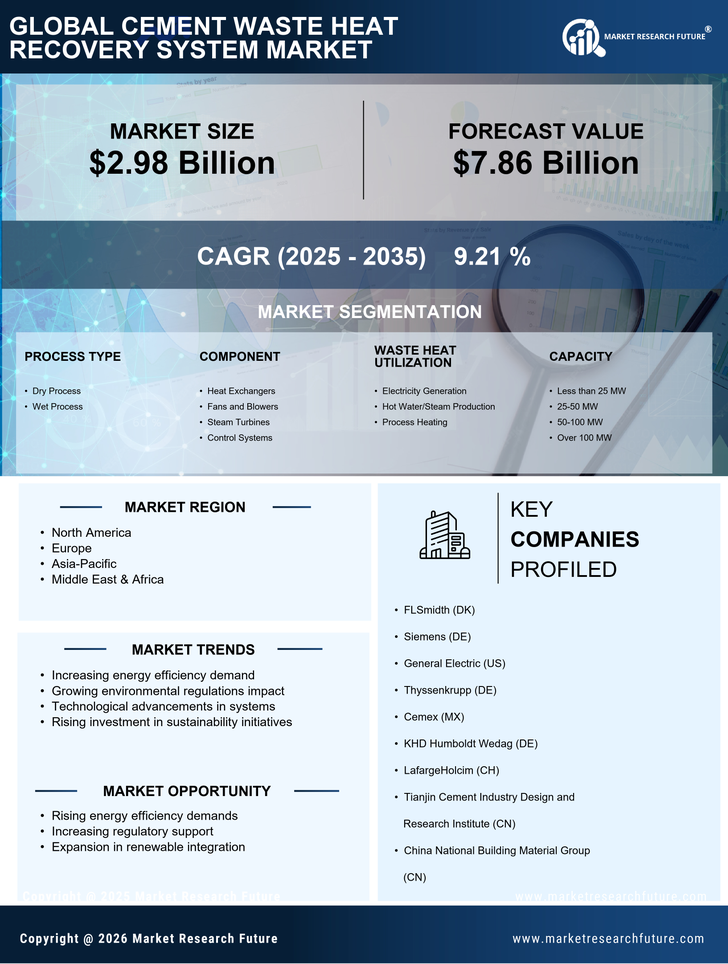

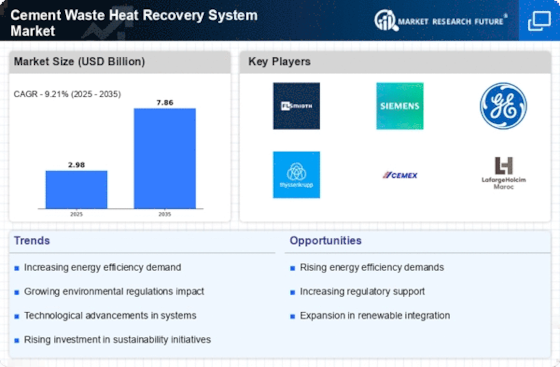

Rising Energy Costs

The Cement Waste Heat Recovery System Market is experiencing a notable surge in demand due to escalating energy costs. As energy prices continue to rise, cement manufacturers are increasingly seeking alternative energy sources to mitigate operational expenses. Waste heat recovery systems offer a viable solution by capturing and reusing heat generated during cement production, thereby reducing reliance on conventional energy sources. This shift not only enhances energy efficiency but also contributes to cost savings, making it an attractive option for cement producers. According to recent data, the implementation of waste heat recovery systems can lead to energy savings of up to 30%, further incentivizing investment in this technology. Consequently, the rising energy costs are likely to drive the growth of the Cement Waste Heat Recovery System Market.

Environmental Regulations

The Cement Waste Heat Recovery System Market is significantly influenced by stringent environmental regulations aimed at reducing carbon emissions. Governments across various regions are implementing policies that mandate lower greenhouse gas emissions from industrial processes, including cement production. Waste heat recovery systems align with these regulations by providing a means to enhance energy efficiency and reduce the carbon footprint of cement manufacturing. For instance, the European Union has set ambitious targets for carbon neutrality, prompting cement companies to adopt innovative technologies such as waste heat recovery. This regulatory landscape not only encourages compliance but also fosters a competitive advantage for companies that invest in sustainable practices. As a result, the increasing emphasis on environmental regulations is expected to propel the growth of the Cement Waste Heat Recovery System Market.

Technological Innovations

The Cement Waste Heat Recovery System Market is witnessing a wave of technological innovations that enhance the efficiency and effectiveness of waste heat recovery systems. Advancements in turbine technology, heat exchangers, and control systems are enabling cement manufacturers to optimize energy recovery processes. For example, the integration of advanced sensors and automation technologies allows for real-time monitoring and management of heat recovery systems, maximizing energy output. Furthermore, the development of modular and scalable systems provides flexibility for cement plants of varying sizes. These innovations not only improve the overall performance of waste heat recovery systems but also reduce installation and operational costs. As a result, the ongoing technological advancements are likely to stimulate investment and growth within the Cement Waste Heat Recovery System Market.

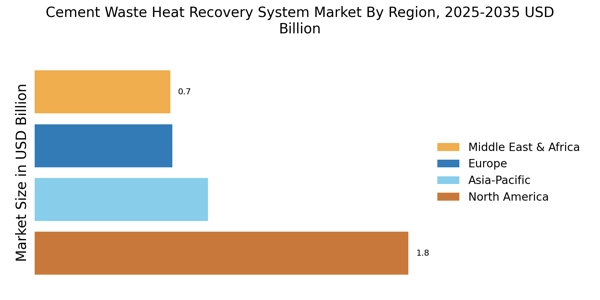

Economic Growth in Emerging Markets

The Cement Waste Heat Recovery System Market is poised for growth, particularly in emerging markets experiencing rapid economic development. As these regions invest in infrastructure and construction projects, the demand for cement is surging. This increased production activity presents an opportunity for cement manufacturers to adopt waste heat recovery systems as a means to enhance energy efficiency and reduce operational costs. Moreover, the availability of government incentives and support for sustainable technologies further encourages the adoption of waste heat recovery systems in these markets. For instance, countries in Asia and Africa are increasingly recognizing the benefits of waste heat recovery, leading to a rise in installations. Therefore, the economic growth in emerging markets is likely to serve as a catalyst for the expansion of the Cement Waste Heat Recovery System Market.

Growing Demand for Sustainable Practices

The Cement Waste Heat Recovery System Market is increasingly driven by the growing demand for sustainable practices within the construction sector. Stakeholders, including consumers and regulatory bodies, are placing greater emphasis on sustainability, prompting cement manufacturers to adopt eco-friendly technologies. Waste heat recovery systems play a crucial role in this transition by enabling the recycling of energy that would otherwise be wasted. This not only reduces the environmental impact of cement production but also enhances the overall sustainability profile of the industry. Recent studies indicate that companies implementing waste heat recovery systems can achieve significant reductions in energy consumption and emissions, aligning with the sustainability goals of the construction sector. Consequently, the rising demand for sustainable practices is expected to bolster the growth of the Cement Waste Heat Recovery System Market.