Sustainability Initiatives

Sustainability is becoming increasingly pivotal in the Cold Stamping Body in White Market. As environmental regulations tighten and consumer preferences shift towards eco-friendly products, manufacturers are compelled to adopt sustainable practices. This includes the use of recyclable materials and energy-efficient processes that minimize carbon footprints. The industry is witnessing a rise in the demand for lightweight components, which contribute to improved fuel efficiency in vehicles. According to recent data, the market for lightweight automotive materials is projected to grow significantly, indicating a shift towards sustainability. Companies that prioritize eco-friendly practices not only enhance their brand image but also gain a competitive edge in the Cold Stamping Body in White Market. This trend is likely to continue as stakeholders increasingly emphasize the importance of sustainability in their operations.

Collaborative Industry Partnerships

Collaborative partnerships within the Cold Stamping Body in White Market are emerging as a strategic driver for growth. Manufacturers are increasingly forming alliances with suppliers, technology providers, and research institutions to leverage shared expertise and resources. These collaborations facilitate the development of innovative solutions that enhance production capabilities and reduce costs. For instance, partnerships focused on research and development can lead to breakthroughs in material science, resulting in stronger and lighter components. Additionally, joint ventures can enable companies to access new markets and expand their customer base. As the industry evolves, these collaborative efforts are likely to play a crucial role in shaping the future landscape of the Cold Stamping Body in White Market.

Rising Demand for Electric Vehicles

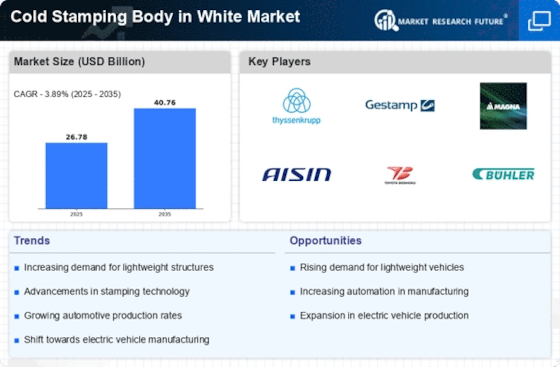

The surge in electric vehicle (EV) adoption is significantly influencing the Cold Stamping Body in White Market. As automakers pivot towards electrification, the need for lightweight and efficient body structures becomes paramount. Cold stamping processes are particularly well-suited for producing the intricate designs required for EVs, which often feature unique shapes and materials. Market data suggests that the EV segment is expected to account for a substantial share of the automotive market in the coming years, driving demand for advanced manufacturing techniques. This shift not only presents opportunities for growth within the Cold Stamping Body in White Market but also necessitates innovation in material selection and design to accommodate the specific requirements of electric vehicles.

Regulatory Compliance and Safety Standards

Regulatory compliance and safety standards are critical drivers in the Cold Stamping Body in White Market. As governments worldwide implement stricter regulations regarding vehicle safety and emissions, manufacturers must adapt their processes to meet these requirements. Compliance with safety standards not only ensures the protection of consumers but also enhances the credibility of manufacturers. The industry is witnessing an increased focus on quality assurance and testing protocols to ensure that stamped components meet regulatory benchmarks. This emphasis on compliance can lead to higher production costs; however, it also fosters innovation as companies seek to develop safer and more efficient products. Consequently, adherence to regulatory frameworks is likely to remain a significant factor influencing the Cold Stamping Body in White Market.

Technological Advancements in Cold Stamping

The Cold Stamping Body in White Market is experiencing a notable transformation due to rapid technological advancements. Innovations in stamping machinery and automation are enhancing production efficiency and precision. For instance, the integration of robotics and artificial intelligence in manufacturing processes is streamlining operations, reducing waste, and improving product quality. As a result, manufacturers are able to produce complex geometries with tighter tolerances, which is crucial for meeting the evolving demands of the automotive sector. Furthermore, the adoption of Industry 4.0 principles is facilitating real-time monitoring and data analytics, allowing for proactive maintenance and optimization of production lines. This technological evolution not only boosts productivity but also positions companies to respond swiftly to market changes, thereby driving growth in the Cold Stamping Body in White Market.