Research Methodology on Composites Market

Overview

The research methodology employed while preparing the report on the global composites market is created to provide an approachable and reliable source of information based on the latest market trends and established market drivers. The analysis is conducted by focusing on both qualitative and quantitative aspects of the composites market.

The market assessment is based on elements such as market size, market trends, market opportunities, projected growth rate and forecast period 2023 to 2030. The primary objects of the research methodology include market segments, dynamics, growth-driving factors, and their impact on the overall composites market. Various sources such as interviews with key industry experts and other relevant stakeholders, industry journals, annual reports, paid and unpaid databases and more assist in comprehensively creating the market report.

Research Approach

The research approach for the report on the global composites market comprises both primary and secondary research methodologies. Primary research includes interviews with key industry experts, surveys and more. Secondary research includes industry journals, literature reviews, and more.

The study is undertaken to provide an accurate, reliable and qualitative research report; therefore, a customized approach is adopted. Market size estimations are achieved through both bottom-up and top-down approaches, while market forecasts and market dynamics are accomplished through both qualitative and quantitative approaches.

Research Sources

The research sources utilized while elaborating the report involve a combination of primary as well as secondary sources to accurately assess the global composites market. Primary sources include interviews with top-level executives and market experts, while secondary sources include industry journals, review articles, and market reports.

• Primary Sources (In-depth Interviews):

In-depth interviews are conducted with CEOs, CFOs, and key opinion leaders.

• Secondary Sources (Industry Journals & Publications):

Wohlers Reports, Industrial Composites Magazine, Plastics Technology, Composites World Magazine, Reifenhauser Group, and other industry journals.

Methodology Covered

The study is conducted using the following two primary research objectives:

• Market Size Estimation:

The market size is estimated through both top-down and bottom-up approaches.

• Market Dynamics & Forecast:

Market dynamics, such as drivers, restraints, opportunities, and challenges are identified and forecasted by using both qualitative and quantitative approaches.

Market Segmentation

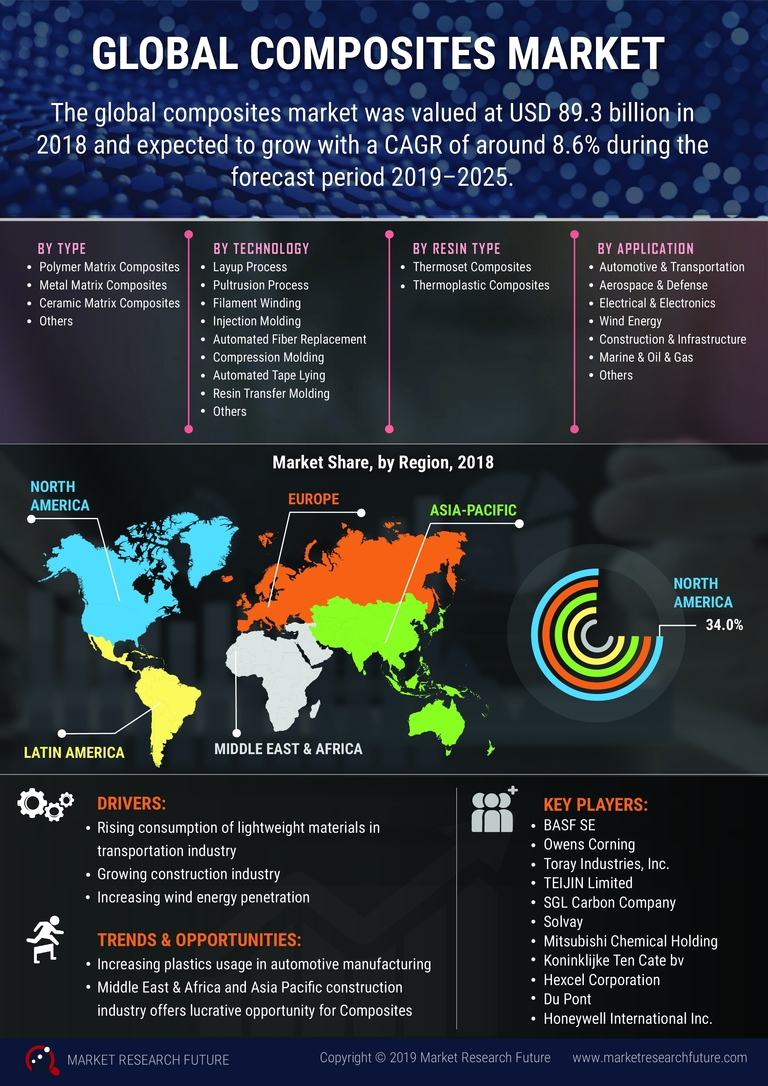

The report has segmented the composites market based on the following parameters:

- By Resin Type: Polyester, Vinyl Ester, Phenolic, Polyurethane, and Others.

- By Fiber Type: Glass Fibers, Carbon Fibers, Aramid Fibers, and Others

- By Application: Aerospace & Defense, Automotive, Maritime, Wind Energy, Construction, and Others

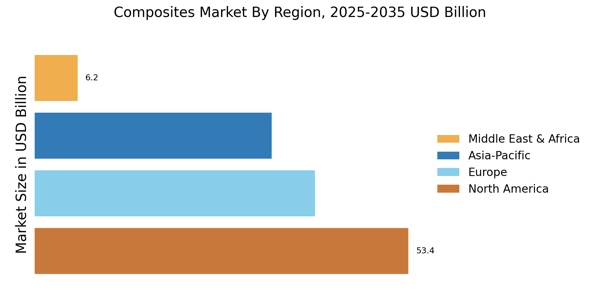

- By Region: North America, Europe, Asia Pacific, Central & South America, and Middle East & Africa.