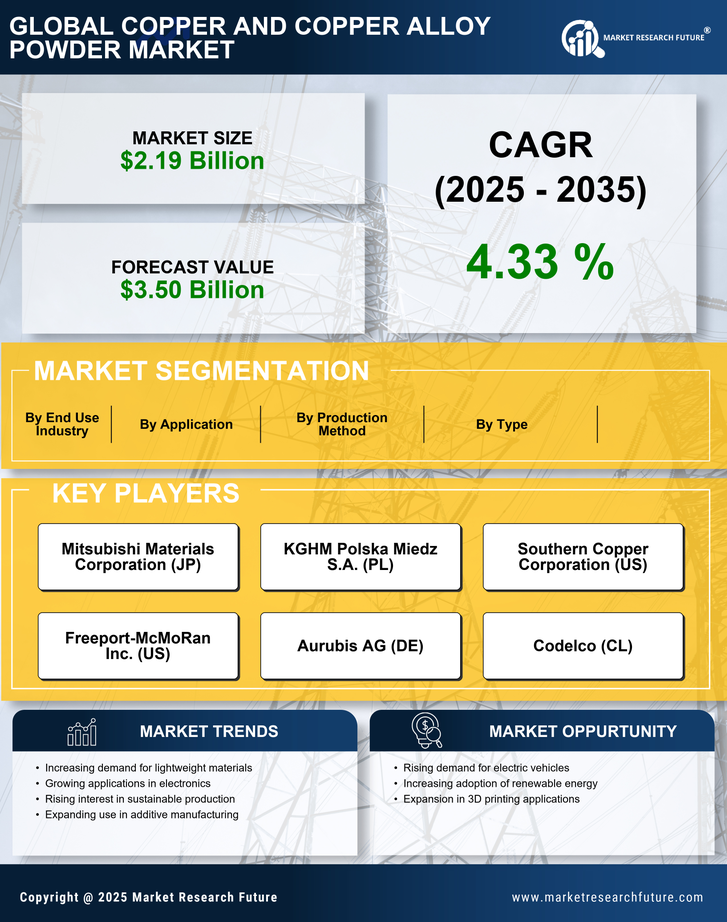

Automotive Industry Growth

The growth of the automotive industry is a vital driver for the Copper and Copper Alloy Powder Market. As the automotive sector evolves towards electric vehicles (EVs) and advanced technologies, the demand for copper materials is increasing. Copper powders are essential in the production of electric motors, batteries, and wiring harnesses, which are critical components of modern vehicles. The market is projected to grow as the automotive industry shifts towards electrification, with an anticipated increase in copper usage per vehicle. In 2025, the demand for copper powders is expected to rise significantly, driven by the transition to EVs and the need for lightweight materials that enhance energy efficiency. This trend highlights the pivotal role of the Copper and Copper Alloy Powder Market in supporting the automotive sector's transformation towards sustainable mobility.

Infrastructure Development

Infrastructure development is emerging as a crucial driver for the Copper and Copper Alloy Powder Market. With ongoing investments in construction and urbanization, the demand for copper materials is on the rise. Copper powders are increasingly utilized in various applications, including construction materials, electrical wiring, and plumbing systems. The market is expected to experience growth as governments and private sectors prioritize infrastructure projects to enhance connectivity and economic development. In 2025, the market for copper powder is projected to expand significantly, driven by these infrastructure initiatives. Moreover, the shift towards smart cities and sustainable infrastructure solutions is likely to further boost the demand for copper powders, as they are integral to energy-efficient systems. This trend underscores the importance of the Copper and Copper Alloy Powder Market in supporting modern infrastructure needs.

Sustainability Initiatives

The increasing emphasis on sustainability initiatives is a pivotal driver for the Copper and Copper Alloy Powder Market. As industries strive to reduce their carbon footprint, the demand for eco-friendly materials has surged. Copper, known for its recyclability, plays a crucial role in sustainable manufacturing processes. The market is witnessing a shift towards the use of copper powders in applications that prioritize environmental responsibility. This trend is further supported by regulatory frameworks that encourage the adoption of sustainable practices. In 2025, the market for copper powder is projected to grow significantly, driven by the need for materials that align with sustainability goals. Companies are increasingly investing in technologies that enhance the recyclability of copper, thereby fostering a circular economy. This focus on sustainability not only meets consumer expectations but also positions the Copper and Copper Alloy Powder Market favorably in a competitive landscape.

Technological Advancements

Technological advancements are reshaping the Copper and Copper Alloy Powder Market, leading to enhanced production methods and applications. Innovations in powder metallurgy and additive manufacturing have opened new avenues for the utilization of copper powders. These advancements enable the production of high-performance components with superior properties, catering to diverse industries such as aerospace, automotive, and electronics. The market is experiencing a notable increase in the adoption of 3D printing technologies, where copper powders are utilized to create intricate designs that were previously unattainable. In 2025, the market is expected to witness a substantial rise in demand for copper powders, driven by these technological innovations. Furthermore, the development of advanced sintering techniques is likely to improve the efficiency of copper powder production, thereby reducing costs and enhancing product quality. This technological evolution positions the Copper and Copper Alloy Powder Market at the forefront of modern manufacturing.

Growing Demand in Electronics

The growing demand in the electronics sector is a significant driver for the Copper and Copper Alloy Powder Market. As electronic devices become increasingly sophisticated, the need for high-conductivity materials has intensified. Copper powders are essential in the production of various electronic components, including connectors, circuit boards, and sensors. The market is projected to expand as the electronics industry continues to evolve, with an estimated growth rate of over 5% annually through 2025. This demand is fueled by the proliferation of smart devices and the Internet of Things (IoT), which require reliable and efficient materials. Additionally, the trend towards miniaturization in electronics is likely to increase the utilization of copper powders, as they offer superior performance in compact applications. The Copper and Copper Alloy Powder Market is thus positioned to benefit from these trends, as manufacturers seek to meet the rising demand for high-quality electronic components.