Expansion of Consumer Electronics Market

The Electrolytic Copper Foil Market is significantly influenced by the expansion of the consumer electronics market. With the proliferation of smart devices, including smartphones, tablets, and wearables, the demand for high-performance electronic components is on the rise. Copper foils play a crucial role in the manufacturing of printed circuit boards (PCBs), which are integral to these devices. Recent statistics indicate that the consumer electronics market is expected to reach a valuation of several trillion dollars in the next few years, further driving the need for quality copper foils. As manufacturers strive to produce lighter, thinner, and more efficient devices, the demand for advanced electrolytic copper foils is likely to increase. This trend suggests a promising outlook for the Electrolytic Copper Foil Market, as it adapts to the evolving landscape of consumer technology.

Technological Innovations in Manufacturing

The Electrolytic Copper Foil Market is experiencing a surge in technological innovations that enhance production efficiency and product quality. Advanced manufacturing techniques, such as electroforming and precision etching, are being adopted to produce thinner and more uniform copper foils. These innovations not only reduce material waste but also improve the electrical conductivity of the foils, making them more suitable for high-performance applications. As a result, manufacturers are likely to see increased demand from sectors such as electronics and renewable energy. The integration of automation and smart manufacturing processes further streamlines operations, potentially leading to cost reductions and higher profit margins. This trend indicates a robust growth trajectory for the Electrolytic Copper Foil Market, as companies strive to meet the evolving needs of their customers.

Regulatory Support for Sustainable Practices

The Electrolytic Copper Foil Market is likely to benefit from increasing regulatory support for sustainable manufacturing practices. Governments worldwide are implementing stringent regulations aimed at reducing environmental impact and promoting recycling initiatives. This regulatory landscape encourages manufacturers to adopt eco-friendly production methods, which can enhance their market competitiveness. The push for sustainability is particularly relevant in the copper foil industry, where recycling and responsible sourcing of raw materials are becoming critical. Recent initiatives suggest that companies focusing on sustainable practices may gain a competitive edge, as consumers increasingly prefer products that align with their values. Consequently, the Electrolytic Copper Foil Market may experience growth as it adapts to these regulatory changes and embraces sustainability as a core business strategy.

Surge in Demand from Renewable Energy Sector

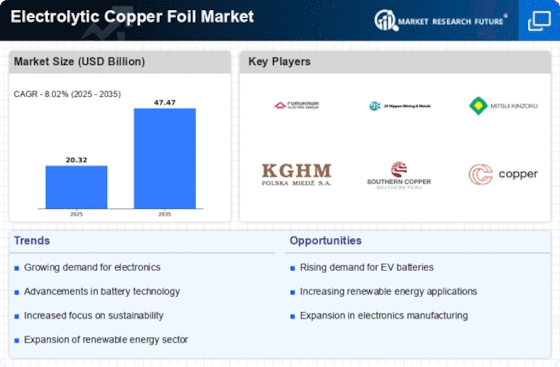

The Electrolytic Copper Foil Market is witnessing a notable increase in demand driven by the renewable energy sector. As the world shifts towards sustainable energy solutions, the need for efficient energy storage systems, such as batteries, is escalating. Copper foils are essential components in lithium-ion batteries, which are widely used in solar energy storage and electric vehicles. Recent data suggests that the battery market is projected to grow significantly, with a compound annual growth rate of over 20% in the coming years. This growth is likely to propel the demand for high-quality electrolytic copper foils, as manufacturers seek to enhance battery performance and longevity. Consequently, the Electrolytic Copper Foil Market stands to benefit from this trend, as it aligns with the global push for cleaner energy alternatives.

Growing Investment in Electric Vehicle Infrastructure

The Electrolytic Copper Foil Market is poised for growth due to increasing investments in electric vehicle (EV) infrastructure. Governments and private entities are allocating substantial resources to develop charging stations and battery production facilities, which are essential for supporting the EV market. As electric vehicles become more mainstream, the demand for high-capacity batteries is expected to rise, thereby increasing the need for electrolytic copper foils. Recent reports indicate that the EV market is projected to grow exponentially, with millions of units expected to be sold annually in the near future. This growth trajectory suggests that the Electrolytic Copper Foil Market will benefit from the heightened demand for quality materials that enhance battery efficiency and performance, positioning it favorably in the evolving automotive landscape.