Rising Demand in Electronics

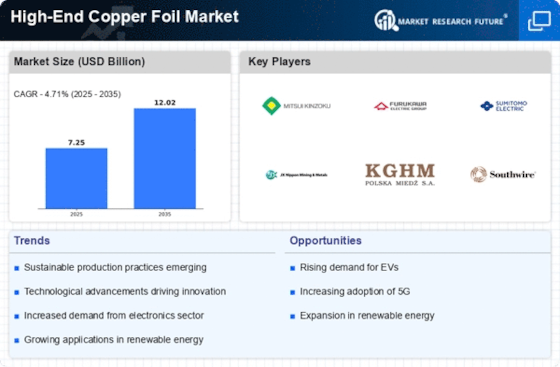

The High-End Copper Foil Market is experiencing a notable surge in demand, particularly driven by the electronics sector. As consumer electronics continue to evolve, the need for high-performance materials, such as copper foil, becomes increasingly critical. In 2025, the demand for copper foil in electronic applications is projected to reach approximately 200,000 metric tons, reflecting a compound annual growth rate of around 5%. This growth is largely attributed to the proliferation of smartphones, tablets, and other portable devices that require advanced circuitry. Furthermore, the shift towards miniaturization in electronic components necessitates the use of thinner and more efficient copper foils, thereby enhancing the overall performance of electronic devices. Consequently, manufacturers are compelled to innovate and adapt their production processes to meet this escalating demand.

Growing Electric Vehicle Market

The expansion of the electric vehicle (EV) market is emerging as a pivotal driver for the High-End Copper Foil Market. As the automotive sector increasingly shifts towards electrification, the demand for high-quality copper foil in battery production is expected to rise significantly. In 2025, the global electric vehicle sales are projected to surpass 10 million units, leading to an increased requirement for copper foil in battery components. This trend is further supported by government initiatives aimed at promoting sustainable transportation solutions. The use of high-end copper foil in EV batteries enhances conductivity and overall performance, making it a critical material for manufacturers. Consequently, the High-End Copper Foil Market is likely to witness substantial growth as automotive companies seek to incorporate advanced materials into their electric vehicle designs.

Increased Focus on Renewable Energy

The High-End Copper Foil Market is also benefiting from the growing emphasis on renewable energy sources. As the world transitions towards sustainable energy solutions, the demand for high-quality copper foil in solar panels and wind turbines is on the rise. In 2025, the renewable energy sector is expected to account for over 30% of global energy production, driving the need for efficient conductive materials. Copper foil plays a crucial role in enhancing the efficiency of solar cells and wind energy systems, thereby supporting the overall performance of renewable energy technologies. This trend indicates a promising future for the High-End Copper Foil Market, as manufacturers align their production capabilities with the increasing demand for sustainable energy solutions. The integration of copper foil in these applications is likely to foster innovation and drive market growth.

Advancements in Manufacturing Techniques

Innovations in manufacturing processes are significantly influencing the High-End Copper Foil Market. Recent advancements, such as electroforming and roll-to-roll processing, have enabled the production of thinner and more uniform copper foils, which are essential for high-performance applications. These techniques not only enhance the quality of the final product but also improve production efficiency, thereby reducing costs. In 2025, it is estimated that the adoption of these advanced manufacturing methods could lead to a 15% increase in production capacity across the industry. This increase is likely to attract new players into the market, fostering competition and driving further technological advancements. As a result, the High-End Copper Foil Market is poised for substantial growth, with manufacturers continuously seeking to optimize their processes to meet the evolving needs of various applications.

Technological Integration in Manufacturing

The integration of advanced technologies, such as artificial intelligence and automation, is reshaping the High-End Copper Foil Market. These technologies facilitate improved quality control, enhanced production efficiency, and reduced operational costs. In 2025, it is anticipated that approximately 40% of copper foil manufacturers will adopt smart manufacturing practices, leading to a more streamlined production process. This shift not only enhances the competitiveness of manufacturers but also allows for greater customization of products to meet specific client needs. As a result, the High-End Copper Foil Market is likely to experience a transformation, with companies leveraging technology to optimize their operations and respond more effectively to market demands. The potential for increased efficiency and reduced waste could further bolster the industry's growth trajectory.