Market Share

Introduction: Navigating Competitive Momentum in High Performance Plastics

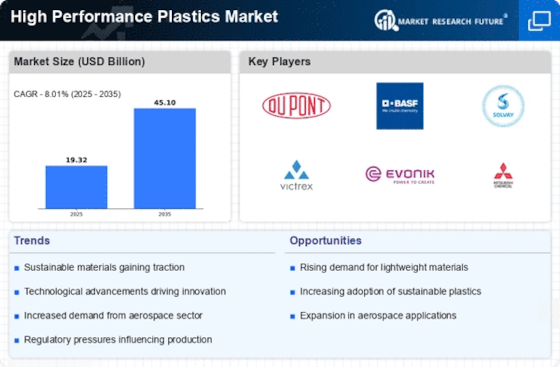

The high-performance plastics market is experiencing a major transformation driven by rapid technological progress, increasing regulatory pressures and changing consumer expectations in terms of both performance and the environment. A number of key players, including the car manufacturers, the materials suppliers and the innovators, are now competing for leadership of the market, using the latest technology, such as artificial intelligence, the Internet of Things and sustainable manufacturing. In this new environment, the manufacturers are focusing on improving the quality and performance of their products, while the IT service companies are automating the supply chains and using big data to optimize them. The green building and biomaterials industries are also changing the game, offering eco-friendly alternatives that meet regulatory requirements. In this situation, where the regional markets, particularly in Asia-Pacific and North America, are growing fast, the strategic deployment of companies will increasingly be focused on collaborations and research and development in order to seize the opportunities.

Competitive Positioning

Full-Suite Integrators

These vendors offer comprehensive solutions across the high performance plastics spectrum, integrating various technologies and services.

| Vendor | Competitive Edge | Solution Focus | Regional Focus |

|---|---|---|---|

| Covestro | Innovative material solutions | Polycarbonate and polyurethane | Global |

| DuPont | Strong R&D capabilities | Engineering polymers | North America, Europe, Asia |

| SABIC | Diverse product portfolio | Thermoplastics and composites | Global |

| BASF | Extensive chemical expertise | High-performance plastics | Global |

Specialized Technology Vendors

These companies focus on niche technologies and advanced materials, providing specialized solutions for high performance applications.

| Vendor | Competitive Edge | Solution Focus | Regional Focus |

|---|---|---|---|

| Toray Industries | Advanced fiber technology | Carbon fiber reinforced plastics | Asia, North America |

| Mitsubishi Chemical | Innovative polymer solutions | Engineering plastics | Asia, Europe |

| Teijin | Sustainability focus | High-performance fibers | Asia, North America |

| 3M | Diverse application expertise | Adhesives and coatings | Global |

Infrastructure & Equipment Providers

These vendors supply the necessary infrastructure and equipment to support the production and processing of high performance plastics.

| Vendor | Competitive Edge | Solution Focus | Regional Focus |

|---|---|---|---|

| PolyOne | Custom color and additive solutions | Specialty polymer formulations | North America, Europe |

| LG Chem | Strong manufacturing capabilities | Engineering plastics | Asia, North America |

| Henkel | Leading adhesive technologies | Adhesives and sealants | Global |

| Solvay | High-performance materials expertise | Specialty polymers | Global |

| Eastman Chemical | Innovative product development | Thermoplastic copolyester | Global |

| Celanese | High-quality engineered materials | Acetyl products and polymers | Global |

| DSM | Sustainability-driven innovation | Engineering plastics | Global |

Emerging Players & Regional Champions

- In this way, Solvay, which has just landed a large order from a major aeronautical manufacturer for lightweight components, is challenging the DuPonts of the world with its higher resistance to heat and chemicals.

- Toray Industries (Japan): Offers advanced composite materials and high-tech films, has recently completed a project in the field of electric vehicles, and provides supplementary services by means of new products and solutions for weight reduction and energy conservation.

- Sabic (Saudi Arabia): Sabic, which specializes in engineering plastics and special polymers, has recently extended its product range with a new line of high-temperature resistant materials for the electronics industry, thus putting it into competition with established suppliers such as BASF.

- Victrex (UK): Known for its PEEK products, recently entered into a partnership with a medical device manufacturer to develop biocompatible materials, challenging established vendors by focusing on niche applications in the healthcare sector.

- Mitsubishi Chemical (Japan): Offers a range of high-performance plastics for various industries, recently launched a new line of eco-friendly polymers, complementing established vendors by addressing sustainability concerns in the market.

Regional Trends: In 2024, there is a marked increase in the use of high-performance plastics in Asia-Pacific, which are in great demand in the aviation and automobile industries for their lightness and toughness. North America continues to lead in technological specialization, particularly in the field of aeronautics, while Europe is concerned with sustainable development and green solutions. In all regions, new players, using new and often disruptive technologies, are carving out niches and threatening the established players by offering solutions adapted to the needs of specific industries.

Collaborations & M&A Movements

- DuPont and BASF entered into a joint venture to develop sustainable high-performance plastics aimed at reducing carbon footprints in automotive applications, enhancing their competitive positioning in the eco-friendly materials segment.

- Celanese Corporation acquired the specialty polymers division of Solvay in early 2024 to expand its product portfolio and strengthen its market share in the high-performance plastics sector, particularly in the electronics and automotive industries.

- Covestro and Mitsubishi Chemical established a strategic partnership to innovate in the field of bioplastics, aiming to capture a growing segment of environmentally conscious consumers and comply with increasing regulatory pressures on plastic waste.

Competitive Summary Table

| Capability | Leading Players | Remarks |

|---|---|---|

| Material Strength | DuPont, BASF | DuPont Kevlar is a fibre which has gained a reputation for its tensile strength and its resistance to wear, and has been used in many applications, especially in the aeronautical and motor industries. And Ultramid, with its high mechanical strength, is used in the most demanding of conditions. |

| Thermal Resistance | 3M, Solvay | 3M's VHB™ tape demonstrates superior thermal resistance, making it ideal for construction and automotive industries. Solvay's KetaSpire® PEEK is recognized for its high thermal stability, often utilized in aerospace and medical devices. |

| Chemical Resistance | Victrex, Eastman Chemical | Victrex's PEEK polymer is highly resistant to a wide range of chemicals, making it suitable for oil and gas applications. Eastman's Tritan™ copolyester is known for its chemical resistance and is widely used in consumer products. |

| Sustainability | Covestro, BASF | Besides its bio-based polycarbonates for use in the automobile and electrical industries, Covestro is also developing bio-based polyurethanes for use in the electronics industry. Product lines like BASF’s biodegradable plastics, for example, are an example of the company’s focus on sustainable solutions. |

| Customization and Versatility | SABIC, Mitsubishi Chemical | Customized high-performance plastics from SABIC, tailored to specific applications, enhance their market value. Similarly, the extensive product range of Mitsubishi Chemicals provides solutions for a wide variety of industries, including automobiles and medical technology. |

Conclusion: Navigating High Performance Plastics Dynamics

High Performance Polymers in 2024 are characterised by intense competition and significant fragmentation, with both established and new players vying for market share. The trend towards innovation and sustainability is evident across all regions. The big companies are able to draw on their established supply chains and brand loyalty, while the newcomers are focusing on cutting-edge capabilities such as artificial intelligence, automation and agility. The ability to integrate sustainable practices will be critical to future success, and companies that prioritise this will gain a competitive edge. Strategic planners must keep a close eye on these developments and align their offerings with the changing demands of the market.

Leave a Comment