High Performance Plastics Size

Market Size Snapshot

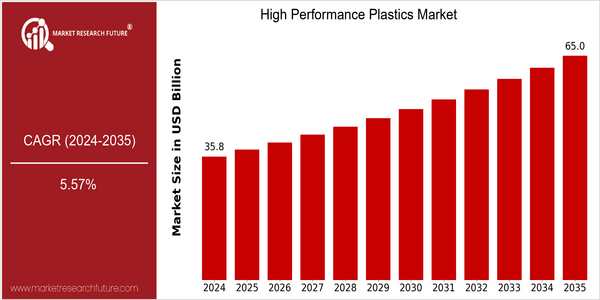

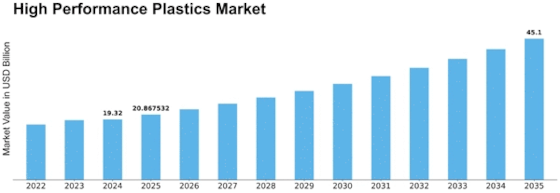

| Year | Value |

|---|---|

| 2024 | USD 35.8 Billion |

| 2035 | USD 65.0 Billion |

| CAGR (2025-2035) | 5.57 % |

Note – Market size depicts the revenue generated over the financial year

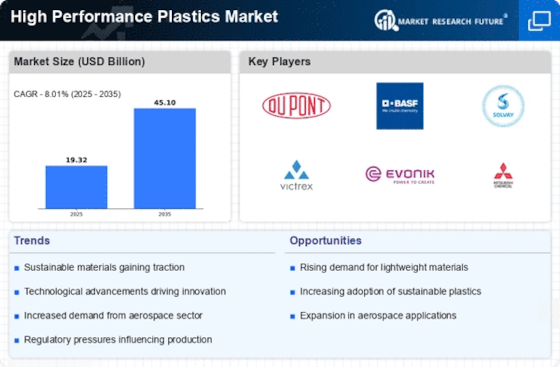

High-Performance Polymers Market is expected to reach a size of $ 358.6 billion by 2024, and is projected to reach $ 650 billion by 2035. It will be growing at a CAGR of 5.57% from 2025 to 2035. The main reason for this growth is the increasing demand for high-performance materials in various industries such as aviation, aerospace, automobiles, electronics and medical care. High-performance polymers are becoming an indispensable material in advanced applications. In addition, the development of new formulations and processing methods for polymers is expected to drive market growth. The use of bioplastics and sustainable materials is gaining momentum, in line with the sustainable development goals of the world. DuPont, BASF and Solvay, as the leading companies, are investing in research and development, forming strategic alliances and launching new products to capture the opportunities. DuPont's recent development of high-performance polymers for electric vehicles is an example of its strategic focus on meeting the needs of the market. High-Performance Polymers Market will be driven by technological innovation and the increasing use of polymers in various industries.

Regional Market Size

Regional Deep Dive

High-Performance Plastics Market is characterized by the increasing demand in various industries such as the automobile, aircraft, electronics, and medical devices. In addition, the market is characterized by a unique geographical dynamic, which is influenced by economic, regulatory, and technological developments. High-Performance Plastics Market is driven by the need for materials that can withstand high temperatures, chemicals, and mechanical stress, which has led to the increased preference for high-performance plastics over traditional materials. Moreover, the market is expected to grow significantly as a result of innovation and sustainable practices in various industries.

Europe

- Europe is leading in the development of bio-based high-performance plastics, with companies like BASF and Covestro investing heavily in sustainable materials to meet stringent EU regulations on plastic waste and environmental impact.

- The European Union's Green Deal is fostering innovation in the high-performance plastics market, encouraging research and development initiatives that focus on recycling and circular economy practices.

Asia Pacific

- The Asia-Pacific region is experiencing rapid industrialization, particularly in countries like China and India, which is driving demand for high-performance plastics in automotive and electronics applications.

- Key players such as Toray Industries and Mitsubishi Chemical are investing in advanced manufacturing technologies to enhance the performance characteristics of their plastic products, catering to the growing needs of local industries.

Latin America

- Latin America is seeing increased investment in high-performance plastics for the automotive sector, with companies like Embraer exploring lightweight materials to enhance aircraft performance and reduce emissions.

- Regulatory frameworks in Brazil are evolving to support the use of advanced materials, encouraging local manufacturers to adopt high-performance plastics in various applications.

North America

- The North American market is undergoing a boom in the use of high-performance plastics in the aircraft industry, driven by the growing use of lightweight materials by the likes of Boeing and Lockheed Martin, which are striving to improve fuel efficiency.

- The regulations for reducing the emissions of carbon monoxide are driving manufacturers to replace metals with high-performance plastics, which are defended by the American Chemistry Council.

Middle East And Africa

- In the Middle East, the oil and gas sector is a significant driver for high-performance plastics, with companies like SABIC focusing on developing materials that can withstand harsh environmental conditions.

- Government initiatives in several African countries are promoting the use of high-performance plastics in construction and infrastructure projects, aiming to improve durability and reduce maintenance costs.

Did You Know?

“High-performance plastics can withstand temperatures ranging from -200°C to over 300°C, making them suitable for extreme environments in industries like aerospace and automotive.” — Plastics Technology Magazine

Segmental Market Size

High Performance Polymers are enjoying robust growth driven by the rising demand from various industries like the aerospace, automotive, and electronics. There are several reasons for this growth. One is the growing demand for lightweight materials that enhance fuel efficiency and performance. Another is the stringent government regulations to reduce carbon emissions. Another reason is the technological advancements in the field of polymers, which have made it possible to develop high-performance materials that withstand extreme conditions. These high-performance polymers are already in use, and the leading companies like DuPont and BASF are introducing new products and processes. The notable projects are the use of PEEK in the components of the aero-space and high-temperature applications in the automobile industry. This market finds its application in electrical insulators, aircraft structural parts, and medical devices. These applications are a result of the macro-economic trends like the push for sustainable products and the need for lightweight materials. The developments in additive manufacturing and nanotechnology will have a great impact on the future of this market.

Future Outlook

High-Performance Polymers (HPP) are a new generation of high-tech polymers. HPPs have a variety of properties that make them suitable for many applications. HPPs have a variety of applications in many fields. HPPs are widely used in the field of high-performance materials. HPPs have been widely used in the field of high-performance materials. HPPs have been widely used in the field of high-performance materials. HPPs have been widely used in the field of high-tech materials. HPPs have been widely used in the field of high-tech materials. HPPs have been widely used in the field of high-tech materials. HPPs have been widely used in the field of high-tech materials. HPPs have been widely used in the field of high-tech materials. HPPs have been widely used in the field of high-tech materials. HPPs are expected to increase their share of the total polymer market in the field of high-tech materials. HPPs are expected to continue to increase their share of the total polymer market in the field of high-tech materials. HPPs will continue to grow as a result of technological development, such as the development of bio-based HPPs and the development of new polymer processing methods. HPPs will continue to grow as a result of regulatory pressure to reduce CO2 emissions and improve product life. HPPs are expected to be widely used in applications where the performance of traditional materials is not satisfactory. HPPs are expected to grow in the field of high-tech materials. The integration of smart materials and the rise of circular economy will continue to shape the trend. HPPs will continue to grow in the field of high-tech materials. As a result, HPPs will continue to grow in the field of high-tech materials. It is therefore necessary for the parties involved in this field to keep an eye on the trend and continue to invest in R & D in order to take advantage of the opportunities that will arise in this dynamic field.

Leave a Comment