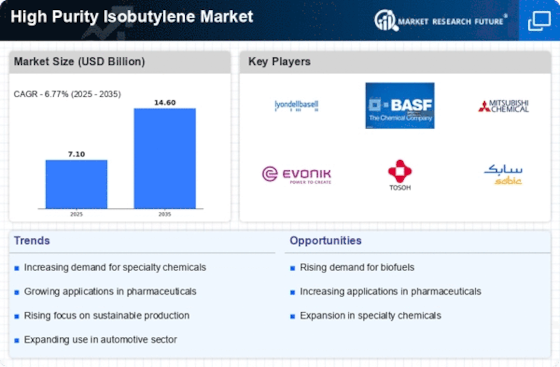

Leading market players are investing heavily in research and development in order to expand their product lines, which will help the High Purity Isobutylene Market, grow even more. Market participants are also undertaking a variety of strategic activities to expand their footprint, with important market developments including new product launches, contractual agreements, mergers and acquisitions, higher investments, and collaboration with other organizations. To expand and survive in a more competitive and rising market climate, High Purity Isobutyleneindustry must offer cost-effective items.

Manufacturing locally to minimize operational costs is one of the key business tactics used by manufacturers in the High Purity Isobutylene industry to benefit clients and increase the market sector. In recent years, the High Purity Isobutylene industry has offered some of the most significant advantages to medicine. Major players in the High Purity Isobutylene Market, including G Zibo Qixiangtengda Chemcial Co., Ltd., Evonik Industries AG., TPC Group, Exxon Mobil Corporation, Bioenergies, LyondellBasell Industries Holdings BV and others, are attempting to increase market demand by investing in research and development operations.

Exxon Mobil firm is a worldwide oil and gas firm headquartered in Houston, Texas, and the largest direct descendent of John D. Rockefeller's Standard Oil. The firm, which was formed by the merging of Exxon and Mobil in 1999, is vertically integrated across the whole oil and gas industry, and it also has a chemicals division that manufactures plastic, synthetic rubber, and other chemical goods. ExxonMobil is headquartered in the Houston suburb of Spring, Texas, but was founded in New Jersey. In 2019, ExxonMobil, a leading manufacturer of high-purity isobutylene, announced the expansion of its Baytown plant's production capacity.

The expansion was designed to address the increased demand for high-purity isobutylene from a variety of end-use industries, including automotive, construction, and healthcare.

BASF SE is a European multinational corporation and the world's largest chemical producer. The company's headquarters are in Ludwigshafen, Germany. BASF has subsidiaries and joint ventures in over 80 countries and runs six integrated manufacturing sites as well as 390 other manufacturing locations throughout Europe, Asia, Australia, the Americas, and Africa. BASF has customers in over 190 countries and serves a wide range of sectors. Despite its size and reach, BASF has gotten little public notice since it stopped manufacturing and selling BASF-branded consumer electronics items.

In 2020, BASF, a prominent manufacturer of high-performance plastics and elastomers, has announced the purchase of Solvay's polyamide division. The acquisition aims to broaden BASF's product offering in high-performance plastics and elastomers by leveraging Solvay's experience in high-purity isobutylene manufacturing.