Market Analysis

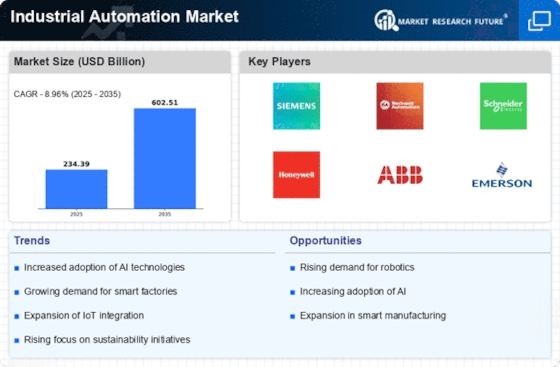

In-depth Analysis of Industrial Automation Market Industry Landscape

The integration of sensors and devices along production lines facilitates equipment monitoring, generating user-friendly data and visuals. This leads to reduced downtime, predictive maintenance, and informed decision-making, factors that drive the expansion of the global industry automation market.

Implementing automated production comprehensively across all facets of a business streamlines information flow and maximizes the benefits of automation. Manufacturers are automating tasks requiring endurance, precision, or those that are repetitive, dull, and demand minimal creativity or specialized expertise. Falling robot costs and escalating labor costs in countries like the United States are driving the trend towards increased automation. Over the next few years, automation is projected to rise steadily, with robot prices anticipated to drop significantly. Industrial manufacturing sectors are under pressure to enhance efficiency through technological infrastructure and smart manufacturing practices, ushering in the era of Industry 4.0. The utilization of modern devices and solutions, such as IPCs (industrial PCs), industrial automation, machine automation technologies, hardware-software integration, among others, is a driving force behind the global industry automation market's growth.

The higher adoption rate of technological advancements in autonomous manufacturing processes has created numerous growth opportunities at both regional and global levels. Regional governments are responding to this trend by implementing strategic initiatives aimed at ensuring long-term economic gains. One such example is the Production Linked Incentives (PLI) scheme in India, which has incentivized manufacturing companies to invest significantly in automating various production processes. Similarly, governments in underdeveloped economies are also launching programs to promote industrial automation, intending to stimulate economic growth within their countries. As automation accelerates in the next decade, the future of the workforce will undergo significant changes.

To mitigate potential challenges associated with automation, governments are taking various actions, including assessing how the implications may vary across employment sectors, geographical areas, and age groups. They are also identifying which employees are most vulnerable to job displacement due to industrial automation. Respective governments are developing sensible and targeted policies to address potential job displacements, supporting companies in retraining their personnel, and providing financial and psychological assistance to those affected. The goal is to harness automation opportunities while minimizing risks.

Leave a Comment