Increasing Industrial Automation

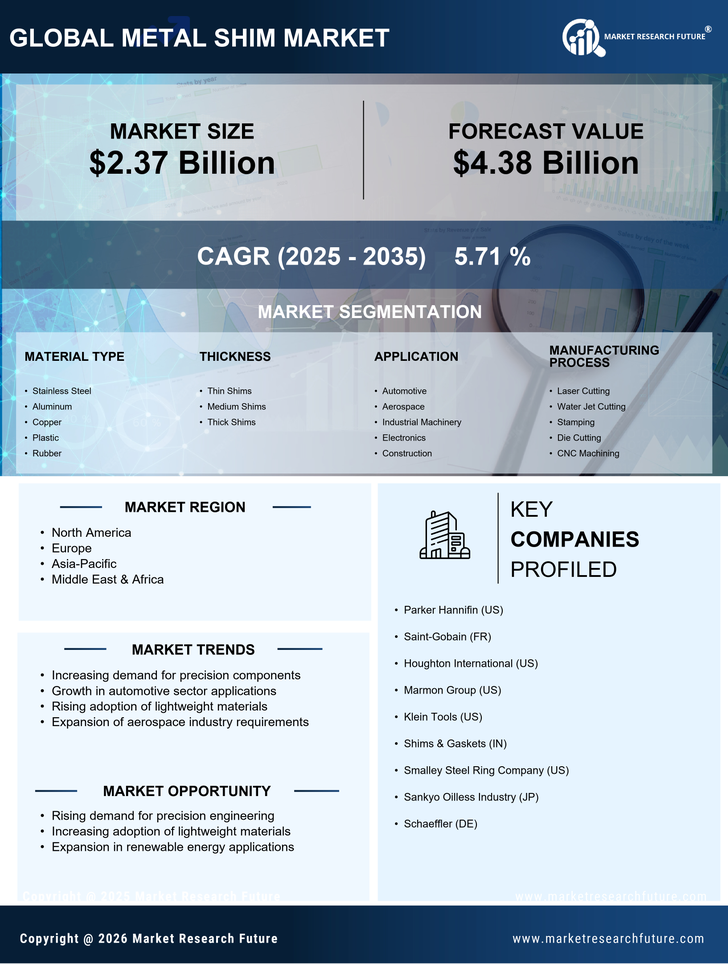

The trend towards industrial automation is significantly influencing the Metal Shim Market. As industries adopt automated systems to enhance productivity and reduce labor costs, the demand for precision-engineered components, including metal shims, is expected to rise. In 2025, the industrial automation market is anticipated to grow at a compound annual growth rate of around 8%, which will likely drive the need for high-quality shims in various applications. These components play a crucial role in ensuring the smooth operation of automated machinery, thereby enhancing overall efficiency. As manufacturers increasingly prioritize automation, the Metal Shim Market is positioned to capitalize on this trend, providing essential components that support the evolving landscape of industrial operations.

Growth in Renewable Energy Sector

The renewable energy sector is emerging as a significant driver for the Metal Shim Market. As the world shifts towards sustainable energy solutions, the demand for components that support renewable technologies, such as wind turbines and solar panels, is on the rise. In 2025, the renewable energy market is projected to expand at a rate of approximately 7%, creating a corresponding demand for high-quality metal shims used in the assembly and maintenance of these systems. This trend indicates a growing recognition of the importance of precision components in enhancing the efficiency and reliability of renewable energy technologies. Consequently, the Metal Shim Market is likely to experience increased opportunities as manufacturers align their offerings with the needs of the renewable energy sector.

Rising Demand in Automotive Sector

The automotive sector is experiencing a notable surge in demand for metal shims, driven by the increasing production of vehicles worldwide. As manufacturers strive for enhanced performance and efficiency, the Metal Shim Market is witnessing a corresponding rise in the need for precision components. In 2025, the automotive industry is projected to account for a significant share of the metal shim market, with estimates suggesting a growth rate of approximately 5% annually. This trend is largely attributed to the growing emphasis on lightweight materials and improved fuel efficiency, which necessitate the use of high-quality metal shims in various automotive applications. Consequently, the Metal Shim Market is poised to benefit from this upward trajectory, as automotive manufacturers increasingly rely on these components to meet stringent performance standards.

Expansion of Aerospace Applications

The aerospace industry is increasingly adopting metal shims for various applications, including aircraft assembly and maintenance. The Metal Shim Market is likely to see substantial growth as the demand for lightweight and durable materials escalates. In 2025, the aerospace sector is expected to contribute significantly to the overall market, with projections indicating a compound annual growth rate of around 6%. This growth is driven by the need for precision-engineered components that can withstand extreme conditions while ensuring safety and reliability. As airlines and manufacturers focus on enhancing fuel efficiency and reducing operational costs, the Metal Shim Market is well-positioned to cater to these evolving requirements, thereby solidifying its role in the aerospace supply chain.

Technological Innovations in Manufacturing

Technological advancements in manufacturing processes are reshaping the Metal Shim Market. Innovations such as precision machining and additive manufacturing are enabling the production of high-quality metal shims with enhanced specifications. These advancements not only improve the accuracy and consistency of shims but also reduce production costs, making them more accessible to various industries. In 2025, the market is expected to witness a shift towards automated manufacturing techniques, which could potentially increase production efficiency by up to 30%. As industries seek to optimize their operations, the Metal Shim Market stands to gain from these technological innovations, which facilitate the creation of customized solutions tailored to specific application needs.