Focus on Energy Efficiency

Energy efficiency is becoming a critical consideration within the Metalworking Machine Market. As manufacturers strive to reduce operational costs and environmental impact, there is a growing emphasis on machines that consume less energy. Recent findings suggest that energy-efficient metalworking machines can reduce energy consumption by up to 30%, making them appealing to cost-conscious manufacturers. This focus on sustainability not only aligns with global environmental goals but also enhances the competitiveness of manufacturers. As a result, the Metalworking Machine Market is likely to see increased demand for energy-efficient solutions, reflecting a broader trend towards sustainable manufacturing practices.

Technological Advancements

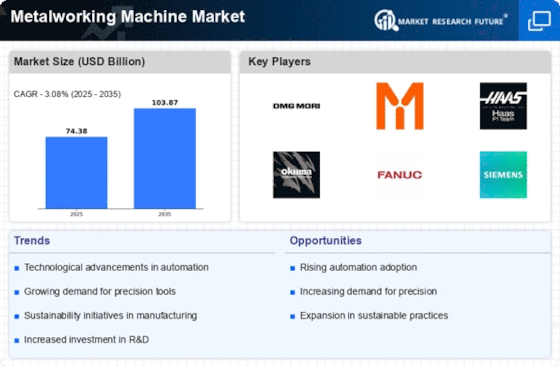

The Metalworking Machine Market is experiencing a surge in technological advancements, particularly in automation and precision engineering. Innovations such as computer numerical control (CNC) machines and advanced robotics are enhancing productivity and accuracy. According to recent data, the adoption of CNC technology has increased by approximately 20% over the past few years, indicating a strong trend towards automation. These advancements not only streamline operations but also reduce labor costs, making them attractive to manufacturers. As industries seek to improve efficiency and output quality, the demand for technologically advanced metalworking machines is likely to grow, further propelling the Metalworking Machine Market.

Growth in Aerospace Manufacturing

The aerospace manufacturing sector is significantly influencing the Metalworking Machine Market. As air travel demand increases, manufacturers are ramping up production of aircraft components, which require high-precision metalworking machines. Data indicates that the aerospace industry is projected to grow at a compound annual growth rate (CAGR) of 4.5% over the next five years. This growth necessitates advanced machining solutions capable of producing lightweight and durable components. As a result, the Metalworking Machine Market is poised to expand, driven by the need for innovative machining technologies that cater to the specific requirements of aerospace applications.

Rising Demand from Automotive Sector

The automotive sector plays a pivotal role in driving the Metalworking Machine Market. With the ongoing evolution towards electric vehicles and advanced manufacturing techniques, the demand for precision metal components is escalating. Recent statistics suggest that the automotive industry accounts for nearly 30% of the total demand for metalworking machines. This trend is expected to continue as manufacturers invest in new technologies to meet the stringent quality and performance standards required in modern vehicles. Consequently, the Metalworking Machine Market is likely to benefit from this rising demand, as automotive companies seek to enhance their production capabilities.

Emerging Markets and Industrialization

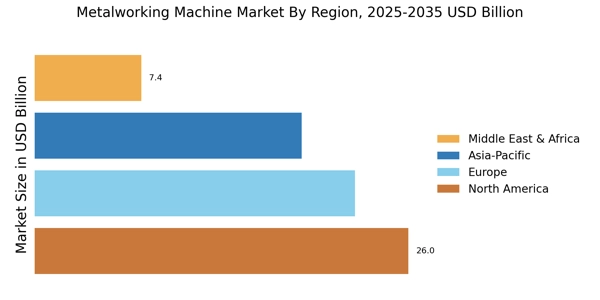

Emerging markets are becoming increasingly important for the Metalworking Machine Market. As countries industrialize, there is a growing need for efficient manufacturing processes, which in turn drives the demand for metalworking machines. Recent reports indicate that regions such as Southeast Asia and South America are witnessing rapid industrial growth, with investments in manufacturing infrastructure. This trend is likely to create new opportunities for metalworking machine manufacturers, as local industries seek to modernize their operations. The Metalworking Machine Market stands to gain from this shift, as companies look to enhance their production capabilities to compete in the global market.