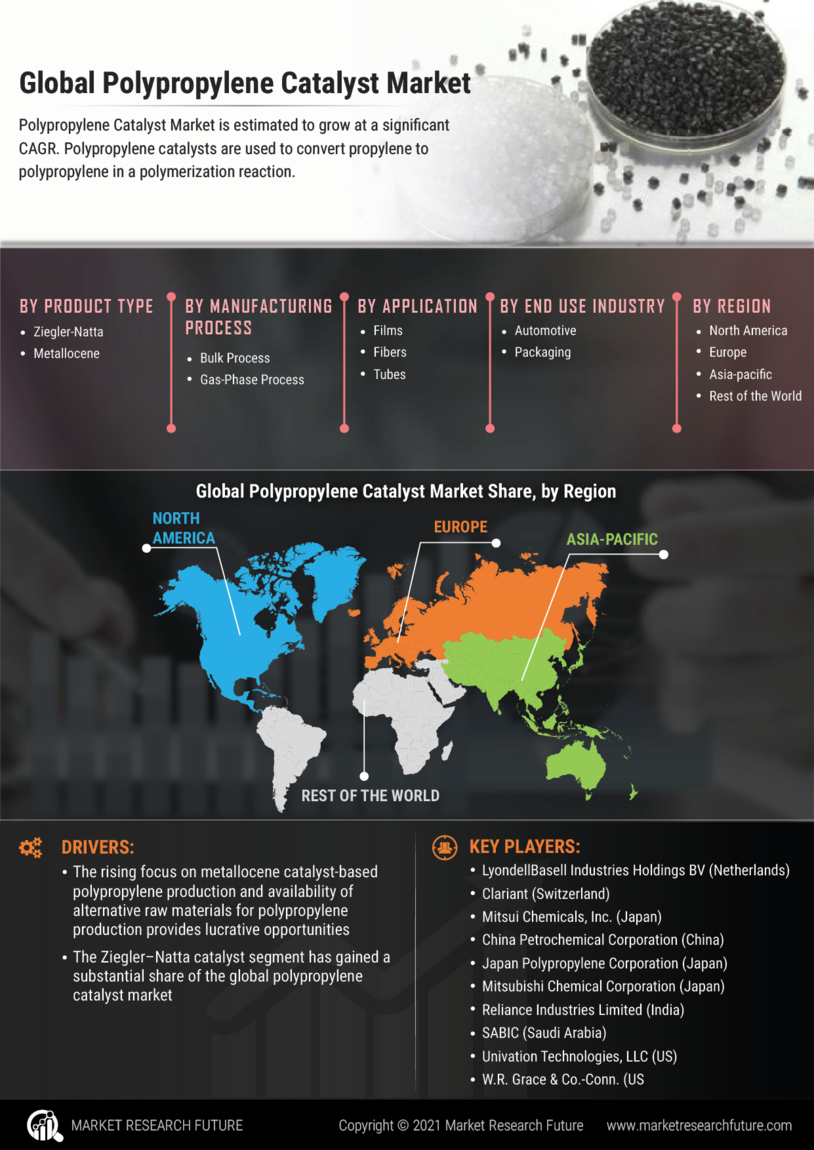

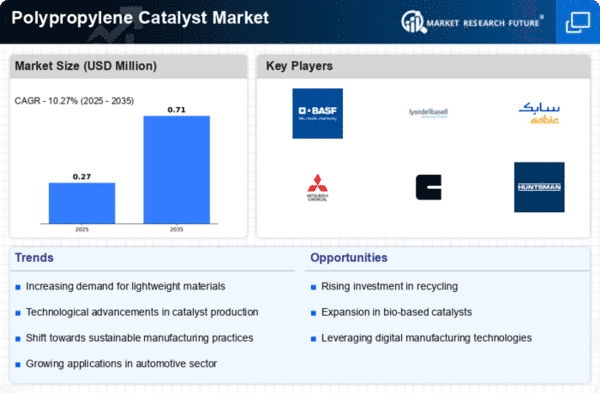

The Polypropylene Catalyst Market is currently characterized by a dynamic competitive landscape, driven by innovation, sustainability, and strategic partnerships. Key players such as BASF (DE),

LyondellBasell (US), and

SABIC (SA) are actively shaping the market through their distinct operational focuses. BASF (DE) emphasizes innovation in catalyst technology, aiming to enhance efficiency and reduce environmental impact. LyondellBasell (US) is pursuing regional expansion, particularly in emerging markets, to capitalize on growing demand. Meanwhile, SABIC (SA) is focusing on sustainability initiatives, aligning its product offerings with global environmental standards. Collectively, these strategies contribute to a competitive environment that is increasingly focused on technological advancement and sustainable practices.In terms of business tactics, companies are localizing manufacturing and optimizing supply chains to enhance operational efficiency. The market structure appears moderately fragmented, with several key players exerting significant influence. This fragmentation allows for a variety of competitive strategies, as companies seek to differentiate themselves through innovation and customer-centric approaches.

In November BASF (DE) announced the launch of a new line of advanced polypropylene catalysts designed to improve production efficiency by 15%. This strategic move is likely to strengthen BASF's market position by offering customers enhanced performance and sustainability, aligning with the growing demand for eco-friendly solutions. The introduction of these catalysts may also set a new benchmark in the industry, compelling competitors to innovate further.

In October LyondellBasell (US) completed the acquisition of a regional catalyst manufacturer, which is expected to bolster its product portfolio and expand its market reach in Asia. This acquisition reflects LyondellBasell's strategy to enhance its competitive edge through vertical integration, allowing for better control over the supply chain and improved customer service. The integration of this new entity could potentially lead to synergies that enhance operational efficiencies and drive growth.

In September SABIC (SA) launched a collaborative initiative with several industry partners to develop sustainable polypropylene solutions. This partnership aims to leverage shared expertise in recycling technologies and sustainable materials. By engaging in such collaborations, SABIC is positioning itself as a leader in sustainability within the polypropylene catalyst sector, which may resonate well with environmentally conscious consumers and businesses.

As of December the competitive trends in the Polypropylene Catalyst Market are increasingly defined by digitalization, sustainability, and the integration of artificial intelligence (AI) in production processes. Strategic alliances are becoming more prevalent, as companies recognize the value of collaboration in driving innovation and addressing market challenges. The competitive differentiation is likely to evolve from traditional price-based competition to a focus on technological advancements, sustainability, and supply chain reliability. This shift suggests that companies that prioritize innovation and sustainable practices will be better positioned to thrive in the future.