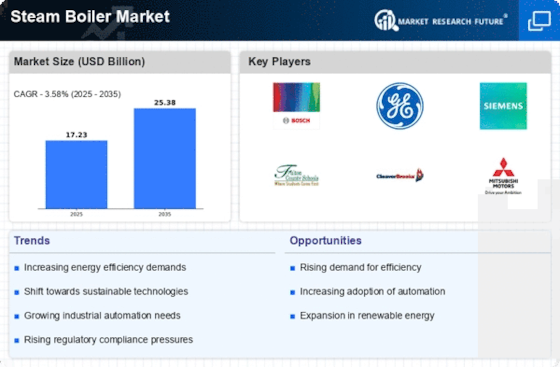

Come November 2022, Mitsubishi Heavy Industries, Ltd. and PLN Indonesia Power will sign a Memorandum of Understanding to commence three feasibility studies on Indonesia Power power plants capable of co-firing less carbon-intensive fuels.

July 2022: For lower emissions and more green technologies, among others, Bosch Industrial Boilers introduced its latest product in the market, which is ELSB electric steam boiler for commercial and industrial steam production. This boiler is designed in such a way that it produces different volumes of stream ranging from 350 to 7500 kg per hour.

March 2022: Vynova Group began to utilize a hydrogen-fired steam boiler system at the Tessenderlo location in Belgium. A second similar steam boiler may be installed by the company. These boilers are expected to help Vynova reduce CO2 emissions annually by approximately 10,000 tonnes at its Tessenderlo facility. Thus far, about eight million euros have been invested in the project.

In 2022, General Electric unveiled the latest iteration of its leading MES software, ProficyÒ Plant Applications, during the ARC Industry Forum’s twenty-sixth edition held at Orlando.

General Electric announces newly available intelligent workload management solution for its PACS solutions in 2022.

In order to achieve these goals by making use of B&W’s advanced biomass and proprietary OxyBrightä carbon capture technologies, Babcock & Wilcox Enterprises, Inc., has partnered with Kiewit Industrial Company in 2022 to create the world’s largest net-negative CO2 biomass-to-energy facility for Fidelis new energy.

August 2021 - Part of BDR Thermea Group, Baxi presents their hydrogen boiler at the UK's first hydrogen house. Two homes in Low Thornley near Gateshead had real-life working examples of hydrogen-powered equipment installed. Baxi invites housing providers to see their boiler in action. By 2025, all products manufactured by Baxi Heating will be low-carbon energy compatible, which means that gas boilers will become “hydrogen-ready” and can easily be adapted to work with hydrogen.

July 2021 - Kawasaki Thermal Engineering (KTE) unveiled a high efficient type of once-through boiler "IF" and "WILLHEAT" series for the international market. With an efficiency rating of 99 percent, both the “IF series” and “WILLHEAT” boilers offer considerable energy savings. The “IF series” achieves boiler efficiency as high as 99 percent due to a newly developed high-performance economizer. Furthermore, this model is capable of producing steam at boiler efficiency of up to 99% even though its heating surface does not exceed 10m2.

Newly introduced are models with equivalent evaporation of 2,500 kg/h and 3,000 kg/h for “WILLHEAT,” a steam boiler having less than 10m2 heated surface area.