Growing Emphasis on Renewable Energy

The Wind Turbine Inspection drones Market is significantly influenced by the increasing global emphasis on renewable energy sources. Governments and organizations are investing heavily in wind energy as part of their sustainability goals. This shift is driving the demand for efficient inspection solutions to ensure the reliability and performance of wind turbines. In 2025, the installed capacity of wind energy is expected to surpass 1,000 GW, necessitating advanced inspection methods to maintain operational efficiency. Drones offer a cost-effective and timely solution for monitoring turbine health, thereby supporting the growth of the renewable energy sector. The rising number of wind farms worldwide further propels the need for specialized inspection drones, making this market a focal point for innovation and investment.

Cost Efficiency and Operational Savings

The Wind Turbine Inspection Drones Market is characterized by the potential for significant cost efficiency and operational savings. Traditional inspection methods often involve extensive manpower and equipment, leading to high operational costs. In contrast, drones can conduct inspections in a fraction of the time and at a lower cost, reducing the need for scaffolding or cranes. As of 2025, it is projected that companies utilizing drones for inspections could save up to 30% on operational expenses. This financial incentive is compelling for wind farm operators, who are increasingly adopting drone technology to enhance their inspection processes. The ability to quickly identify maintenance needs also minimizes downtime, further contributing to overall cost savings.

Increased Focus on Safety and Risk Management

The Wind Turbine Inspection Drones Market is increasingly focused on safety and risk management, particularly in hazardous environments. Traditional inspection methods often expose workers to dangerous heights and adverse weather conditions. Drones mitigate these risks by allowing for remote inspections, thereby enhancing worker safety. As of 2025, it is anticipated that the adoption of drones will reduce workplace accidents in the wind energy sector by up to 40%. This heightened focus on safety not only protects personnel but also aligns with corporate responsibility initiatives. Furthermore, the ability to conduct thorough inspections without human presence in risky areas is likely to become a standard practice, reinforcing the importance of drones in the wind turbine inspection landscape.

Regulatory Developments Supporting Drone Usage

The Wind Turbine Inspection Drones Market is benefiting from favorable regulatory developments that facilitate the use of drones in various sectors, including energy. Regulatory bodies are increasingly recognizing the advantages of drone technology for inspections, leading to streamlined approval processes and operational guidelines. In many regions, regulations are evolving to allow for beyond visual line of sight (BVLOS) operations, which significantly enhances the efficiency of wind turbine inspections. As of 2025, it is estimated that over 60% of wind farm operators will adopt drone technology for routine inspections, driven by these regulatory changes. This trend not only promotes safety and efficiency but also encourages investment in drone technology, further propelling market growth.

Technological Advancements in Drone Capabilities

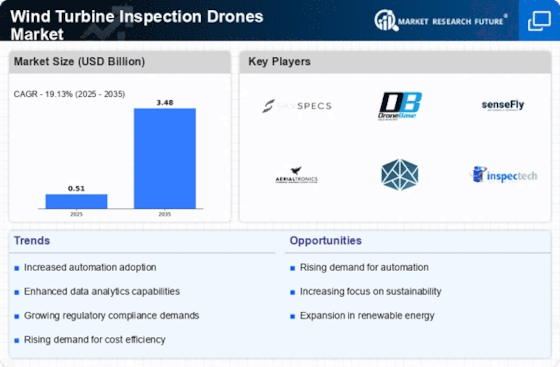

The Wind Turbine Inspection Drones Market is experiencing a surge in technological advancements that enhance drone capabilities. Innovations such as improved imaging systems, AI-driven analytics, and enhanced battery life are transforming inspection processes. For instance, drones equipped with thermal imaging can detect heat anomalies in turbine components, indicating potential failures. The integration of machine learning algorithms allows for predictive maintenance, reducing downtime and operational costs. As of 2025, the market for drone technology in wind turbine inspections is projected to reach USD 1.5 billion, reflecting a compound annual growth rate of 15%. These advancements not only improve inspection accuracy but also increase safety by minimizing the need for human intervention in hazardous environments.

.png)