Rising Health Awareness

The increasing awareness regarding health and hygiene among consumers appears to be a primary driver for the Antimicrobial Additives Market. As individuals become more conscious of the importance of cleanliness, the demand for products containing antimicrobial properties is likely to surge. This trend is particularly evident in sectors such as healthcare, food packaging, and consumer goods, where the presence of harmful microorganisms poses significant risks. According to recent estimates, the antimicrobial additives market is projected to grow at a compound annual growth rate of approximately 6.5% over the next few years. This growth is indicative of a broader shift towards prioritizing health and safety in everyday products, thereby enhancing the market's potential.

Technological Innovations

Technological advancements in the development of antimicrobial additives are likely to play a crucial role in shaping the Antimicrobial Additives Market. Innovations such as nanotechnology and the creation of new chemical formulations are enhancing the efficacy and safety of these additives. For example, the introduction of silver nanoparticles has shown promising results in providing long-lasting antimicrobial effects without compromising material integrity. As manufacturers invest in research and development to create more effective and environmentally friendly solutions, the market is expected to expand. This focus on innovation not only meets consumer demands but also aligns with regulatory standards, further propelling market growth.

Regulatory Support and Standards

The establishment of stringent regulations and standards regarding hygiene and safety is influencing the Antimicrobial Additives Market positively. Governments and health organizations are increasingly mandating the use of antimicrobial solutions in various applications, particularly in healthcare and food safety. Compliance with these regulations is becoming essential for manufacturers, thereby driving the demand for antimicrobial additives. For instance, the Food and Drug Administration has set guidelines that encourage the use of antimicrobial agents in food packaging to enhance safety. This regulatory landscape suggests that as compliance becomes more critical, the market for antimicrobial additives will likely see a corresponding increase in demand.

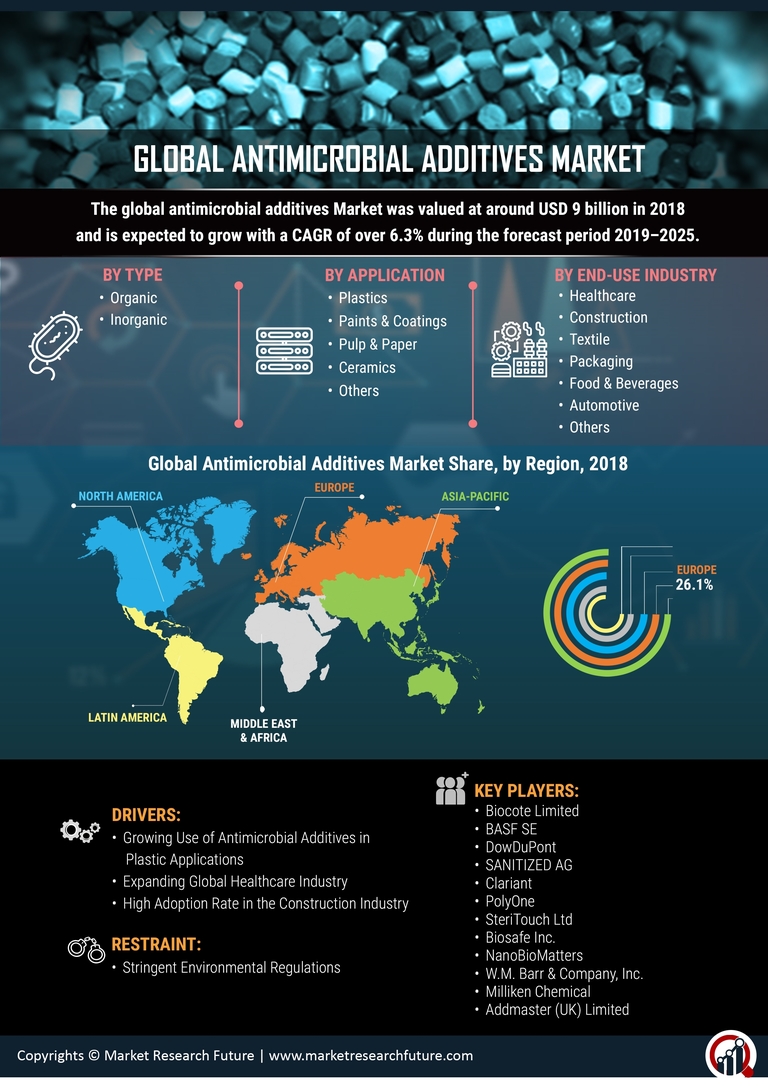

Expanding Applications Across Industries

The versatility of antimicrobial additives is driving their adoption across various industries, which significantly contributes to the growth of the Antimicrobial Additives Market. These additives are utilized in a wide range of applications, including textiles, plastics, coatings, and construction materials. For instance, the textile industry has increasingly integrated antimicrobial properties into fabrics to enhance durability and hygiene. Furthermore, the construction sector is incorporating these additives into materials to prevent microbial growth, thereby extending the lifespan of buildings. This broad applicability suggests that the market could experience sustained growth as industries continue to recognize the benefits of incorporating antimicrobial solutions into their products.

Sustainability and Eco-Friendly Solutions

The growing emphasis on sustainability and eco-friendly products is emerging as a significant driver for the Antimicrobial Additives Market. Consumers are increasingly seeking products that not only provide antimicrobial benefits but also align with environmental standards. Manufacturers are responding by developing biodegradable and non-toxic antimicrobial additives that meet these consumer preferences. This shift towards sustainable solutions is likely to attract a broader customer base, particularly among environmentally conscious consumers. As the market evolves, the integration of sustainability into product development may become a key differentiator, potentially enhancing the competitive landscape within the antimicrobial additives sector.